That's basically what it comes down to, different designs & how much pressure the different designs can apply.

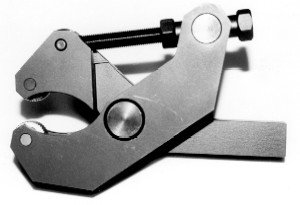

I've always called the old Aloris #19 a clamp style. Not sure if Aloris is the actual designer of this style & not sure of the actual proper names of all the different styles. Like this below except this is a shop made one. They usually have a thumb wheel/nut in front of the pivot to adjust pressure. The pivots can only handle so much & will flex when too much force is applied. Some clamp styles have just one pivot instead of two.

View attachment 312755

Then there are straddle types. Below are the 2 different styles I have know as the straddle type. However I suppose the clamp style above can be considered a straddle type. The heavier duty version is much like a scissor type where the adjuster is behind the pivot. The smaller straddle type has a smaller adjuster that works much like the clamp style above.

View attachment 312756

View attachment 312757

Then there's yet another style called a straddle type. It's the style that Aloris currently offers. I believe Aloris no longer makes the #19 clamp style with a thumb nut. I have a small Dorian one in this style.

View attachment 312760

For the standard scissor type there is simply a bolt & nut that holds the 2 arms & shank together. The Eagle Rock heavy duty type also uses a bolt to hold the arms together but instead of a nut the bolt threads directly into the much beefier mount on the shank & is also secured with a set screw to adjust play/twist under pressure.

I don't oppose one style over the other. They all have their advantages & disadvantages. I'm certainly no expert on knurling (or anything related to this hobby), these were just my observations when I searched for knurling tools. There's yet even more styles for form knurlers like the 3 wheel style. Use whatever works for you is what I do, bump knurlers included. Still need to play with my cut knurlers that I bought like 2 yrs ago.