-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Calculating shear strength of bolts on corrugated roads

- Thread starter malmac

- Start date

Hahaha  That's a highway! That's barely corrugated at all

That's a highway! That's barely corrugated at all

Below is part of the Gibb River Road. It is a State Highway too, but it will shake your fillings out of your teeth, because the corrugations change in frequency as the soil profile changes. So you virtually can't find a speed at which the vibrations stop....

Below is part of the Gibb River Road. It is a State Highway too, but it will shake your fillings out of your teeth, because the corrugations change in frequency as the soil profile changes. So you virtually can't find a speed at which the vibrations stop....

- Joined

- Sep 5, 2014

- Messages

- 428

Even those ones look shallow ! Those ones on the Mitchell Falls run, it comes off the Gibb, were an honest 20cm or 8" deep. Luckily I was driving a hire ute. Not my truck. The problem is guys will air down to get the cushion, but the tires then will overheat with all the flexing. They blow a lot of tires on those roads.

- Joined

- Jun 7, 2016

- Messages

- 361

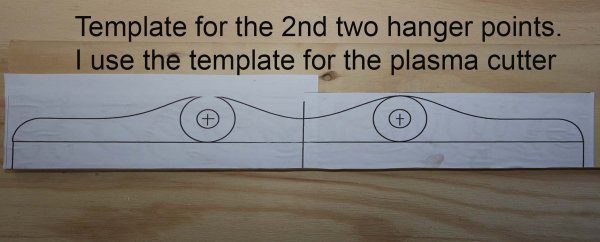

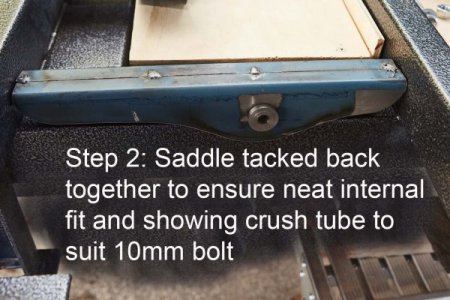

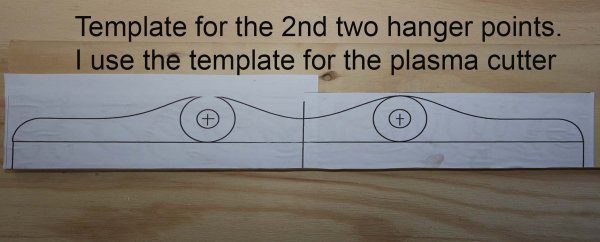

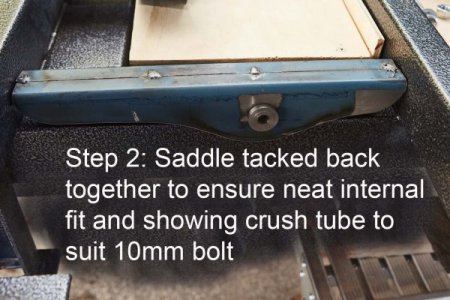

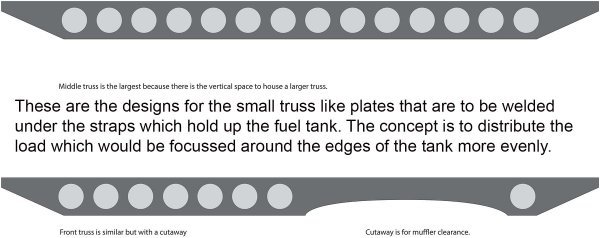

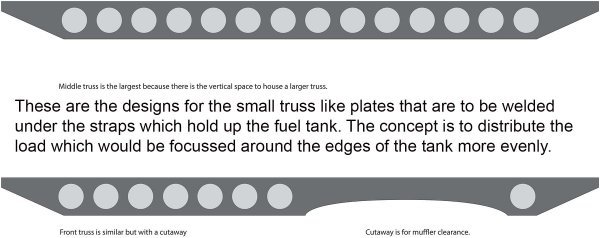

Definitely going with the strap hangers that earlier posts have suggested. Here is a progress report in pics of how I ma reinforcing the mounting points for the strap hangers. Given the 2mm wall thickness of the RHS tray frame I figure the mounting points need to be reinforced. Here is my approach to make saddles which spread the load. Also planning to have three straps rather than just have two.

Thanks again to everyone for your ideas - much appreciated.

Mal

Thanks again to everyone for your ideas - much appreciated.

Mal

- Joined

- Jun 7, 2016

- Messages

- 361

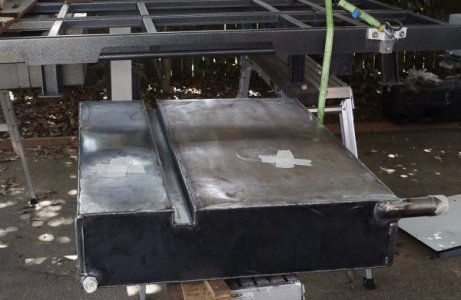

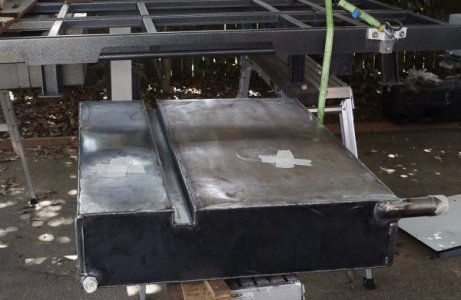

I forgot to post this pic. This is actually the tank back from the fabricators. Building the plywood model has resulted in a perfect fit into the location on the tray. This week I will take it down and have it powder coated to reduce rust on the outside. Taped patches on the top are where the breathers will screw in.

- Joined

- Jun 7, 2016

- Messages

- 361

The 40 x 5 mm straps which support the tank have a major shortcoming in design. They may spread the load across their flat surface but they fail to add any support to the centre of the tank. So I am going to weld a bar across in a vertical plane which should help to provide a measurable level of support to the centre of the tank. To lighten the weight of these addistions I plan to drill 40mm holes with a 15mm space between them. The bar will be 60mm x 5mm. My calculations mean a 30% reduction in weight, however I do not know how much I have reduced their load carrying capacity.

- Joined

- Dec 9, 2016

- Messages

- 1,133

Nice work.

Fyi, in case you weren't aware.....

They sell chemical tank lining kits that are marketed mainly to the motorcycle world that would be perfect to use to protect against corrosion inside the tank.

Fyi, in case you weren't aware.....

They sell chemical tank lining kits that are marketed mainly to the motorcycle world that would be perfect to use to protect against corrosion inside the tank.