Hi all,

Back from Korea, snowed first week I was there. Enjoyed kimchi and soju.

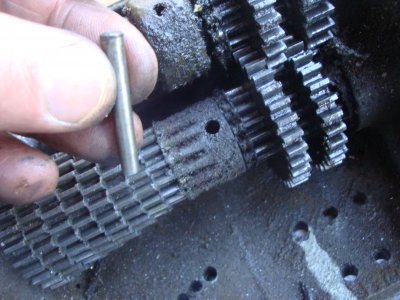

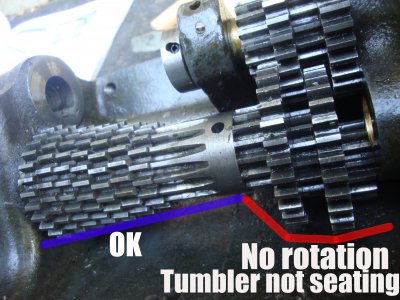

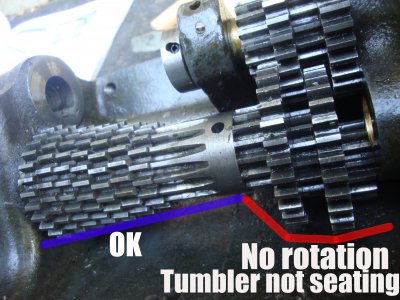

Returned and reassembled the gearbox. One big problem I noticed is that the gears on the central shaft that connect with the gears from the top shaft are locked and don't spin (see red line area). (I didn't connect the assembly to the lathe, just hand spinning test). As well, the tumbler on that side does not engage in any of the holes. It follows the keyway OK but comes up short about 3/8" from each hole.

I'm puzzled what is causing this and definitely want to find out before proceeding any further.

The gears on the other side as well as the entire central shaft rotates freely by hand (blue line area)

The top gears all rotate when they are not hooked up with the gears on the central shaft.

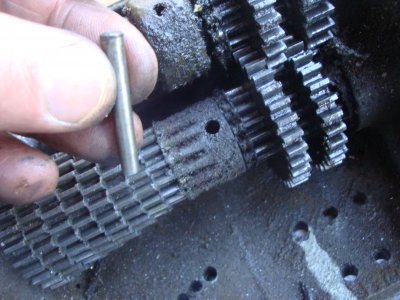

BTW, the photo with the writing was taken as I was in the process in driving in the central shaft so that is why the last 2 gears are not yet seated. As you know, I snapped photos of each and every step.

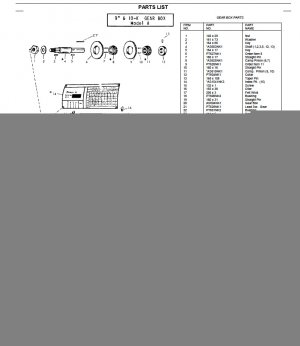

I'm also attaching a photo of the gearbox before it was dissassembled and cleaned. All gears are in the correct size and sequence.

Any help would be most appreciated as I thought I was so close to finishing this component!

Cheers

Dave

Back from Korea, snowed first week I was there. Enjoyed kimchi and soju.

Returned and reassembled the gearbox. One big problem I noticed is that the gears on the central shaft that connect with the gears from the top shaft are locked and don't spin (see red line area). (I didn't connect the assembly to the lathe, just hand spinning test). As well, the tumbler on that side does not engage in any of the holes. It follows the keyway OK but comes up short about 3/8" from each hole.

I'm puzzled what is causing this and definitely want to find out before proceeding any further.

The gears on the other side as well as the entire central shaft rotates freely by hand (blue line area)

The top gears all rotate when they are not hooked up with the gears on the central shaft.

BTW, the photo with the writing was taken as I was in the process in driving in the central shaft so that is why the last 2 gears are not yet seated. As you know, I snapped photos of each and every step.

I'm also attaching a photo of the gearbox before it was dissassembled and cleaned. All gears are in the correct size and sequence.

Any help would be most appreciated as I thought I was so close to finishing this component!

Cheers

Dave