- Joined

- Feb 28, 2021

- Messages

- 251

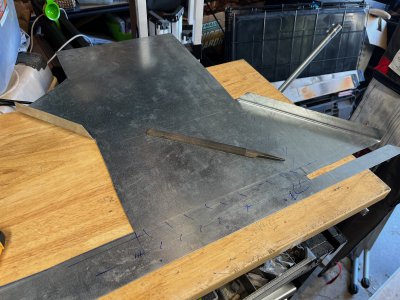

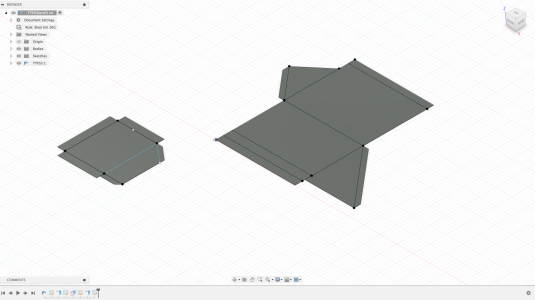

I bent up.a steel glove box for the C10 to replace the cardboard original I shredded putting in ducts

It ate far more time than I expected, but it was mostly fun.

Some production stills including the CAD(Cardboard-aided design) work

It ate far more time than I expected, but it was mostly fun.

Some production stills including the CAD(Cardboard-aided design) work