I use a drag knife on a vacuum table to cut my gaskets.

I would hate to think what they would look like if I did them with a scissors and knife.

Cutting two, one for a spare.

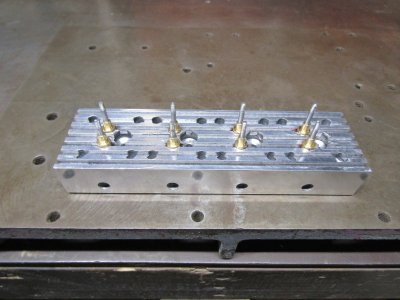

I drilled, counter bored and tapped the four spark plug holes in the head.

Then I installed the newly cut head gasket, cylinder head, and a small flywheel to check for compression..

All four cylinders give a good kick back when the the flywheel is flipped.

All good for now.

I need a proper flywheel so I found these pieces under the bench.

Here is the result.

The flywheel is 4" in diameter and 1" wide and weighs 3lbs.

That should be about right.

Now to give it a coat of paint.

Thanks for looking

Ray