-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

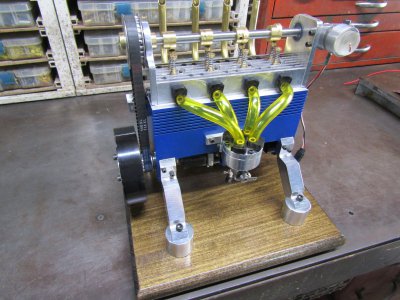

4 Cylinder Inline Engine

- Thread starter rdean

- Start date

- Joined

- Feb 2, 2014

- Messages

- 1,069

Since I have very little cooling the run time will be limited to less than 5mins.How long do you allow it to run?

Have you ever tried placing a load on one?

I have a V twin that runs a generator for a load to allow for slow running.

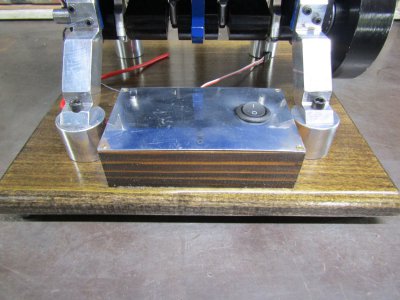

I have had a couple of busy days with other responsibilities but I did get some time today to work on the engine.

Finished the box for the electronics.

And installed the plug wires.

What do you think?

Thanks for looking

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,069

Thanks Robert

Well I did get some time today and put the gas tank together with some 5min epoxy. I also made a tank stand and installed both on the engine.

And a little closer up picture.

On all of my other engines that use this type of carburetor I have installed a throttle lever. The lever is either hard to move or moves by itself so there won't be one on this engine. I installed a brass weight on the carb lever to hold it against the throttle stop at the idle position. I also added a brass knob to the throttle stop screw that is easy to grip and turn. When starting the engine I will turn the idle stop screw in 1 turn first and then start the engine. I will then back out the screw to set the idle speed desired and the high speed is still available by lifting the weight with your finger.

That's the way I hope it will work.

Thanks for looking

Ray

Well I did get some time today and put the gas tank together with some 5min epoxy. I also made a tank stand and installed both on the engine.

And a little closer up picture.

On all of my other engines that use this type of carburetor I have installed a throttle lever. The lever is either hard to move or moves by itself so there won't be one on this engine. I installed a brass weight on the carb lever to hold it against the throttle stop at the idle position. I also added a brass knob to the throttle stop screw that is easy to grip and turn. When starting the engine I will turn the idle stop screw in 1 turn first and then start the engine. I will then back out the screw to set the idle speed desired and the high speed is still available by lifting the weight with your finger.

That's the way I hope it will work.

Thanks for looking

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,069

This has been the easiest first time startup of any of my model engines. I haven't changed the valve timing or the ignition timing settings that I made while engine assembly. The carb main needle factory setting was close right out of the box. My counter weight on the throttle lever works even better than I had hoped. Throttle response is good and reliable. All cylinders are firing and pulling in equal strength. The fuel flow can be seen in the lines and seems to the same on all cylinders. I will be using this design on any future engine builds. My distributor is working just fine but the miter gears are a little noisy. The gas tank holds 1/2oz of fuel and is good for 3 to 5 mins of run time depending on the engine speed. The atmospheric intake valves have not been a problem at any speed. Low speed idle has been recorded at 900rpms but I think it can be lower when broken in. Highest temperature recorded was 175 degrees at the exhaust port on number 3 cyl. The engine block is so massive that it acts as a heat sink to keep the temp down. I let it cool off completely between runs.

I want to thank everyone who left comments and likes along the way it is appreciated.

Thanks for looking

Ray