B

BRIAN

Forum Guest

Register Today

Hi all

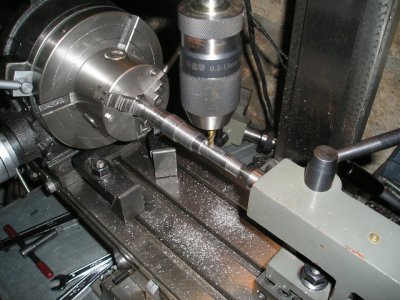

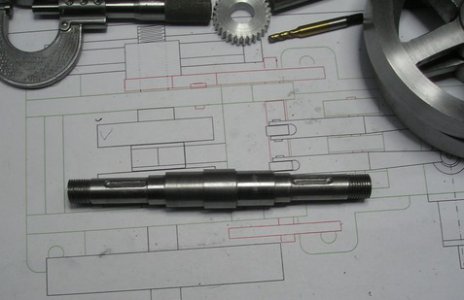

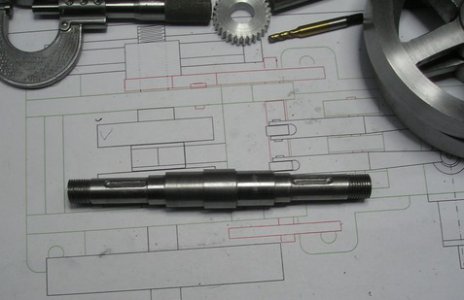

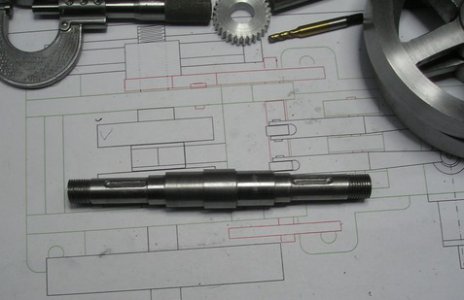

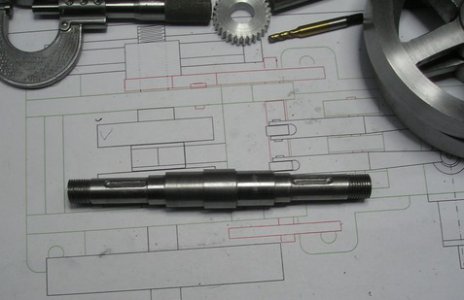

Having returned from Christmas in Scotland, with two 1/2" X 20 nuts. it's time to thread the ends of the crank shaft.

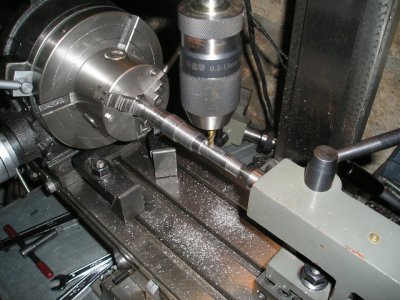

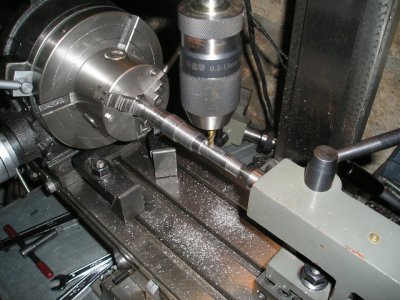

In the picture of the set up you can see that I use a dial gauge to measure the depth of cut, so I don't rely on the dials

just set the gauge to zero when the tool touches the work.

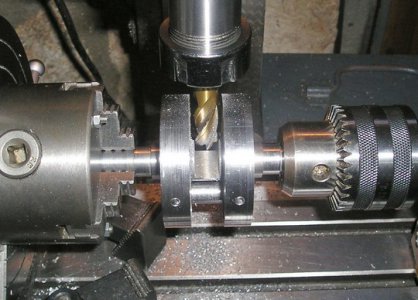

Then on to the mill to cut the keyways for the flywheel and timing gear.

The second full keyway is because, in the future I want to drive a V belt from inside the rear flywheel.

Next job is to cut the keyways in the flywheels.

Brian.

Having returned from Christmas in Scotland, with two 1/2" X 20 nuts. it's time to thread the ends of the crank shaft.

In the picture of the set up you can see that I use a dial gauge to measure the depth of cut, so I don't rely on the dials

just set the gauge to zero when the tool touches the work.

Then on to the mill to cut the keyways for the flywheel and timing gear.

The second full keyway is because, in the future I want to drive a V belt from inside the rear flywheel.

Next job is to cut the keyways in the flywheels.

Brian.