-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 Phase Emergency Stop Switch

- Thread starter Canus

- Start date

Can you use the top item, circuit breaker only for your need? There are other variations without the fuse/breaker, which is basically 3 phase switch, you would pull down and up a handle to turn on or off. Unless you want a touch to shutdown button style, which is like a toggle. 3 phase is a heavy duty and it's hard to have a light touch cut off. High voltage is also a danger. There may not be a simple solution and cheap for this. Unless you can find a used set up somewhere people don't use anymore and throw away. I keep a pile of them.

- Joined

- Mar 19, 2018

- Messages

- 296

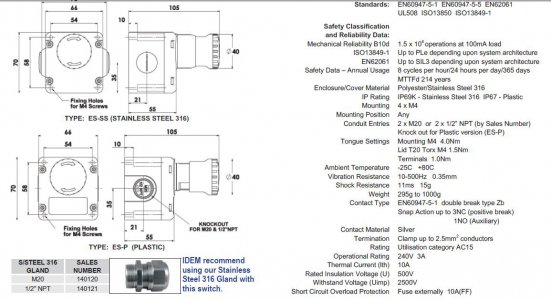

The part that would make me think perhaps that isn't a good choice is the "Operational Rating" of 3A. Most 3 phase machines would use more than that. You would need one that could handle the full current level the machine will draw if you are not using a contactor or similar. The smallest I would use is the amperage level on the motor nameplate. Anything less risks various failure modes that could well result in the e-stop failing to stop the motor. Which in my mind would be worse than not having one at all. If it were me, I would likely want a large safety margin as well, 2x or so. Sadly, that is not going to be cheap.

- Joined

- Nov 26, 2017

- Messages

- 1,517

If you go with an industrial type of switch, you buy the actuator and then buy the contactor block that screws to the back of the actuator body.

Here is one type you can buy through McMaster Carr. There are other designs that use the same principle. Just do a search in MC for 22 or 30 mm push button switches.

www.mcmaster.com

www.mcmaster.com

Here is one type you can buy through McMaster Carr. There are other designs that use the same principle. Just do a search in MC for 22 or 30 mm push button switches.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

- Joined

- Jun 12, 2014

- Messages

- 4,814

The issue with most E-Stop switches is that they cannot handle the current load of the motor which I assume is 2-3 Hp and you usually do not want 3 phase power/current switched at the front panel/machine. Typically, as others have noted, is to switch the contractor coil. You can buy an integrated contactor/thermal overload with E-Stop in an enclosure that could be mounted on the side or somewhere near the front. Having a thermal overload for the motor is probably a good idea. You would need to specify the voltage and the amperage of your motor.

Enclosed Start Stop, E Stop Motor Starter Compressor Saw Grinder 0.5Hp to 12HP | eBay

12 HP. 3 Phase 575V. 12 HP. 3 Phase 440V. 10 HP. 3 Phase 380V. 5.5 HP. 3 Phase 220V. 3 HP. 1 Phase 220V. 1 HP. 1 Phase 120V. Select Cover :E Stop Button or Start Stop Pushbutton. The Starter is Suitable for Three Phase and Single Phase Motors.

www.ebay.com

As others stated, you need a motor starter.

It s a REQUIEMENT !

your motor has zero protection so overload cantoast the motor.

The starter should allow "remote control" so simple off the shelf panel switches solve that.

Many already built surplus items on ebay.

Sent from my SAMSUNG-SM-G930A using Tapatalk

It s a REQUIEMENT !

your motor has zero protection so overload cantoast the motor.

The starter should allow "remote control" so simple off the shelf panel switches solve that.

Many already built surplus items on ebay.

Sent from my SAMSUNG-SM-G930A using Tapatalk

- Joined

- Feb 13, 2017

- Messages

- 2,138

My understanding of VFDs is that there should be no switches between the VFD and the motor. Dual speed switch excepted. Reversing is done through the VFD. However, the VFD should have an "E-Stop" function available that can be remoted. Two wires and a NC latching pushbutton should do the job. Worst case is to interrupt line power to the VFD.

.

.