The other day I posted about the PVC bushings I am making for a customer:

http://www.hobby-machinist.com/thre...in-your-shop-today.14637/page-277#post-425712

They came out fine so far. I wound up doing the corner rounding operation by hand on my router table, cut the time down on that part of the operation from about 1 minute to about 10 seconds per piece. Don't know why I didn't think of that in the first place.

There is one more operation I need to do. The bushings need to be split with a cut that is tangent to the ID. My original intent was to do this by hand on the bandsaw. Unfortunately the results were not satisfactory so I had to come up with a better plan.

It turns out that Harbor Freight has a little tiny chop saw that has a 2 inch blade on it. The chop saw is not useful to me, but the blades are, and they sell 3 packs of replacement blades. The blades are 2 inch dia, and 0.027 thick, made of M2 HSS, or so the package says. Nice little slitting saws, about $10 for a 3 pack.

And a 2 inch diameter blade will just reach deep enough to do the job.

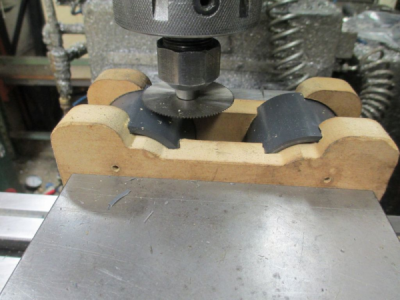

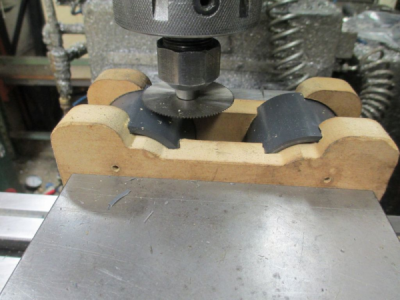

So how to hang onto and locate the parts while slitting? So here's what I came up with, a set of really soft jaws for the mill vice made of MDF. Since I only have 100 pieces to do, a temp MDF fixture will be fine. The groove locates the part and keeps it from collapsing onto the saw blade while making the cut. The PVC wants to spring inward when cut. The part fits snug in the groove and is forced to hold its shape. The parts also sit flush with the bottom of the vice to make loading easier.

This operation is relocating the bolt holes because I'm an idiot.

Kurt vice bolt holes are 0.9375 from the BOTTOM, not the top.

And this is the setup. I haven't tried it yet, I finished the fixture up at about 22:00 this evening so I'll get a fresh start on it in the morning, after I've had my first 1/2 gallon of coffee

. This is the time of night that I start making stupid mistakes.

I expect about 1 minute cycle time for the 2 parts in this setup, so with knocking off 2 minutes per part with some program changes on the first operation, it brings the total time per part to just over 5 minutes. Yeah, I can live with that

Of course I'm not counting the setup time in the total.

. This is the time of night that I start making stupid mistakes.

. This is the time of night that I start making stupid mistakes.