- Joined

- Feb 2, 2013

- Messages

- 3,627

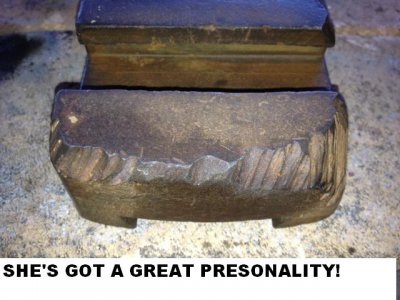

I never brazed with a carbon torch but I do a lot of carbon air arc gouge work shaving down large welds and gouging out welds for repairs it is very easy to shape stuff with an air arc gouging rig and it has the benefit of not putting a lot of heat into the work. I wonder if the air arc would work the same on the brazed area to shave it down.

bob

i have not considered using the air arc for excess brazing material removal, but i'm sure it would work!!!

for the delicate work i'm going to use a flapper disc on the 4.5" grinder and the Dremmel for finer work.

as always thanks for your continued support and interest.

my intention is to inspire others to take up any kind of torch and get to fixn' your broken cast iron!!!!

don't be afraid, you can do do it!!!!