- Joined

- Feb 2, 2013

- Messages

- 3,627

I made some brazing repairs to Henrietta's badly crashed compound rest in the last episode...

i used the Twin Carbon Arc to achieve the build up, i was not able to continue the practice on this repair, my carbons became too short an i was not able to continue until i receive some more A/C copper coated electrodes.

in the interest of moving things along and as to not get too stagnated on an irrelevant issue such as to how the brazing was accomplished, i decided to break out the old oxy/acetylene rig and braze the rest of the build up.

i placed the compound rest back into the 350* for an hour then turned off the stove and let the casting cool on fire bricks.

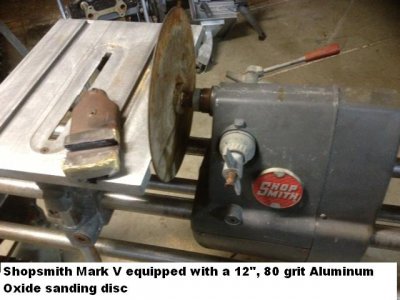

i'll take more pictures as i start knocking the brazing back down.

as always,

thanks for taking the time to read these posts.

i'll do my best to describe the up coming operations.

i used the Twin Carbon Arc to achieve the build up, i was not able to continue the practice on this repair, my carbons became too short an i was not able to continue until i receive some more A/C copper coated electrodes.

in the interest of moving things along and as to not get too stagnated on an irrelevant issue such as to how the brazing was accomplished, i decided to break out the old oxy/acetylene rig and braze the rest of the build up.

i placed the compound rest back into the 350* for an hour then turned off the stove and let the casting cool on fire bricks.

i'll take more pictures as i start knocking the brazing back down.

as always,

thanks for taking the time to read these posts.

i'll do my best to describe the up coming operations.