- Joined

- Feb 2, 2013

- Messages

- 3,627

Well, i Went and started the brazing repair by Twin Carbon Arc Torch :welding:

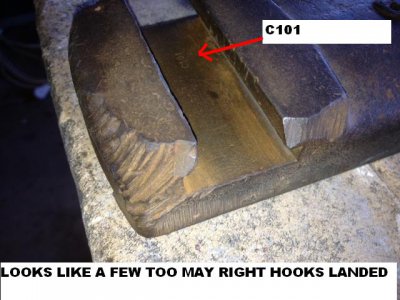

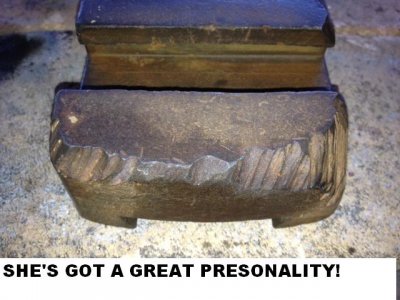

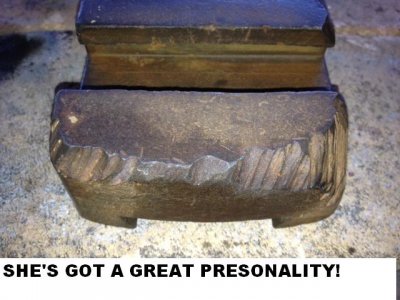

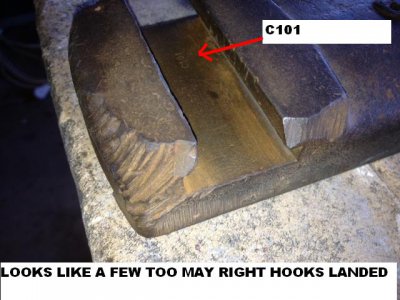

here are a few pictures of the old gal....

she fell down from the top of the ugly tree and hit every branch to the bottom.

as you can see, she's been hurt before!

Fire bricks inside the oven for slow cooling.

Fire bricks inside the oven for slow cooling.

The fire bricks stay warm for a long time

The fire bricks stay warm for a long time

i'm taking my time to make this repair, it may take 2 or 3 nights to get it to the way i want it.

who knows maybe longer...

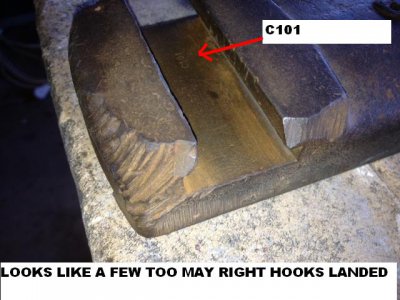

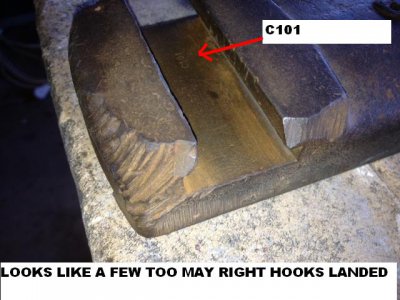

here are a few pictures of the old gal....

she fell down from the top of the ugly tree and hit every branch to the bottom.

as you can see, she's been hurt before!

Fire bricks inside the oven for slow cooling.

Fire bricks inside the oven for slow cooling. The fire bricks stay warm for a long time

The fire bricks stay warm for a long timei'm taking my time to make this repair, it may take 2 or 3 nights to get it to the way i want it.

who knows maybe longer...

Last edited: