- Joined

- Aug 29, 2019

- Messages

- 1,165

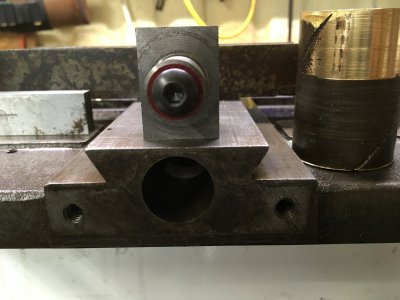

I got this far tonight. Still need to bore and tap the hole for the lead screw. Somehow, I missed the center line of the stem by about .060. I think it may have been the cheap digital calipers I was using to lay out the block. I put new battery in it before I started but was having trouble getting it to zero so batteries in and out several times and may have put the old battery back in. I left myself plenty of meat just in case something like this happened. My eyes are getting terribly bad as well. Just had a complete Diabetic eye exam and got new trifocals. Maybe tomorrow I will bore the cross hole for the acme thread and tap it. I drilled and tapped the stem 5/16-18 for the button head because I hate ball oilers. I think they cause a lot of damage because people either can't see them or are such a pain to get oil into. I have some new 5/16 ball oilers just hate them. Going back and looking at the pictures I can see how I had the punch mark off center from the beginning. I was having trouble seeing the line when I was sawing it. Had to use a flash light and still hard for me to see.

Attachments

-

IMG_3452.JPG373.9 KB · Views: 12

IMG_3452.JPG373.9 KB · Views: 12 -

IMG_3443.JPG371.9 KB · Views: 12

IMG_3443.JPG371.9 KB · Views: 12 -

IMG_3444.JPG401.6 KB · Views: 12

IMG_3444.JPG401.6 KB · Views: 12 -

IMG_3445.JPG383 KB · Views: 11

IMG_3445.JPG383 KB · Views: 11 -

IMG_3446.JPG365.4 KB · Views: 11

IMG_3446.JPG365.4 KB · Views: 11 -

IMG_3447.JPG453.7 KB · Views: 10

IMG_3447.JPG453.7 KB · Views: 10 -

IMG_3448.JPG347.3 KB · Views: 8

IMG_3448.JPG347.3 KB · Views: 8 -

IMG_3449.JPG362.2 KB · Views: 8

IMG_3449.JPG362.2 KB · Views: 8 -

IMG_3450.JPG344.8 KB · Views: 8

IMG_3450.JPG344.8 KB · Views: 8 -

IMG_3451.JPG366 KB · Views: 219

IMG_3451.JPG366 KB · Views: 219