- Joined

- Oct 19, 2011

- Messages

- 127

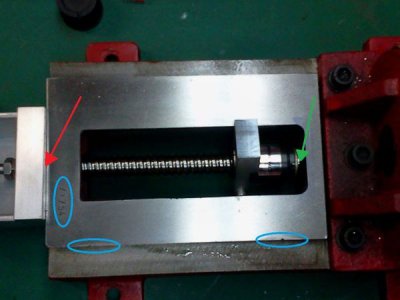

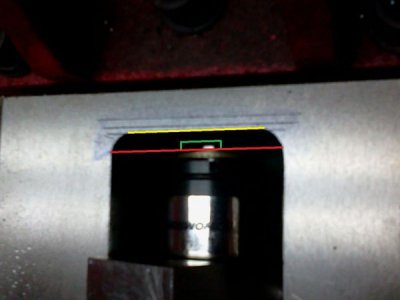

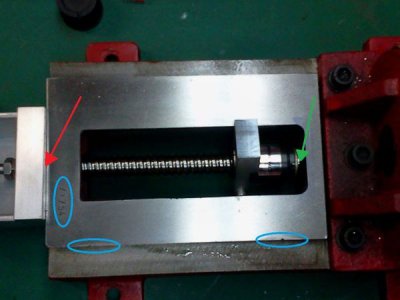

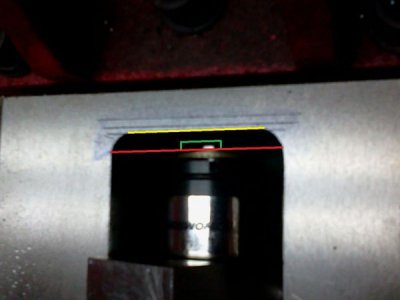

My camera batteries were dead so I used my cell phone camera to take a couple of pics. The quality of the pics isn't great so I drew a couple of lines with MS paint to try to clear up the details I was talking about in my last post.

This first pic gives a good overview of a couple of things. The red arrow shows where the ball screw was protruding out the front of the base casting and not letting the aluminum motor bracket sit flush. The green arrow shows where the other end of the ball screw was hitting the base casting, which was causing the bracket mounting problem at the other end. The blue ovals are circling the areas that were dimpled or dented by the factory during manufacturing.

In this second pic I tried to show a close up of the clearance I milled into the base but the photo came out pretty bad. The red line is where the opening in the casting originally stopped at. The yellow line is how far back I milled it for clearance. The green line is showing where the end of the ball screw sits now that it has clearance. The gap between the green and yellow lines is about 1/16" with the motor bracket installed and sitting flush against the front of the casting.

I'm going to change out the batteries in my camera so I can be sure to get better pics next time.

This first pic gives a good overview of a couple of things. The red arrow shows where the ball screw was protruding out the front of the base casting and not letting the aluminum motor bracket sit flush. The green arrow shows where the other end of the ball screw was hitting the base casting, which was causing the bracket mounting problem at the other end. The blue ovals are circling the areas that were dimpled or dented by the factory during manufacturing.

In this second pic I tried to show a close up of the clearance I milled into the base but the photo came out pretty bad. The red line is where the opening in the casting originally stopped at. The yellow line is how far back I milled it for clearance. The green line is showing where the end of the ball screw sits now that it has clearance. The gap between the green and yellow lines is about 1/16" with the motor bracket installed and sitting flush against the front of the casting.

I'm going to change out the batteries in my camera so I can be sure to get better pics next time.

Last edited: