- Joined

- May 27, 2016

- Messages

- 3,477

OK - I see it now. The differences seem to be in the wheels, and the style of jack levelers. Yours has screw-knobs. The one in (my) picture has some sort of lever handle jack-up.@graham-xrf That's not quite the same base. Mine is the Shop Fox D2058A base which has a weight rating of 1300 lbs.

Shop Fox D2058A Adjustable Mobile Base, Large : Amazon.ca: Tools & Home Improvement

Shop Fox D2058A Adjustable Mobile Base, Large : Amazon.ca: Tools & Home Improvementwww.amazon.ca

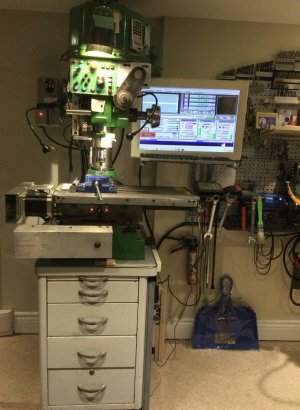

It's rock solid in use. Moves just fine as well though it's hard to get it going; a 700 lb mill on a 50 lb stand with drawers full of tooling, the whole thing is probably north of 800 lbs.

The drawers are all on 100 lb capacity full extension slides. 1/2" Baltic Birch ply drawer boxes.

For both of them, they seem to only have leveling for front-to-back, (2 jacks), and nothing for side-to-side. They still look useful for most machines if on a relatively level floor.