- Joined

- Sep 19, 2019

- Messages

- 109

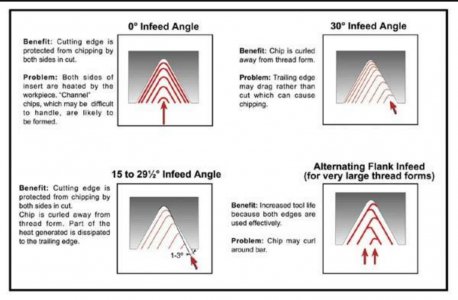

Thanks Tom, that's where I was headed, just couldn't get it in print.If you’re cutting threads with the compound, close is not always good enough if you want to cut good 60 degree threads. There have been a multitude of posts on here about folks cutting screwed up threads (pardon the pun) because they set their compound more than 30 degrees from perpendicular to the spindle axis, or less than 60 degrees from parallel to the spindle axis if you prefer. But, like others have pointed out, if you use the cross slide to advance the cutter, the compound angle is irrelevant. Hope this clears up more confusion than it causes.

Tom

But, if you're tool is ground with a good edge & angle and the tip set right with your work the angle of your compound can be off a bit (plus or minus a degree) and you'll cut good threads.

Like Tom said though if you use the cross feed it'll work.