- Joined

- Feb 15, 2020

- Messages

- 399

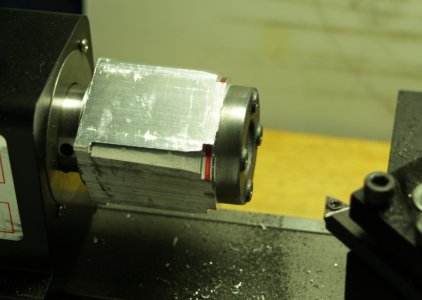

I could be wrong, but if you remove a part from its holding device and re-position it isn't that a new setup? My understanding is that if you swap a part in a mill vice you introduce a new error. I wanted to avoid that.

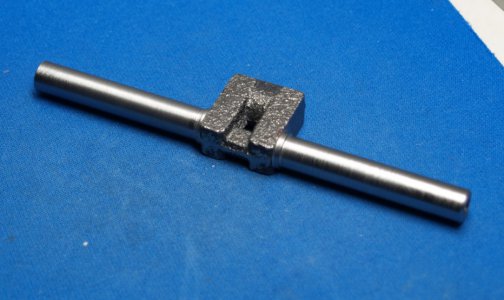

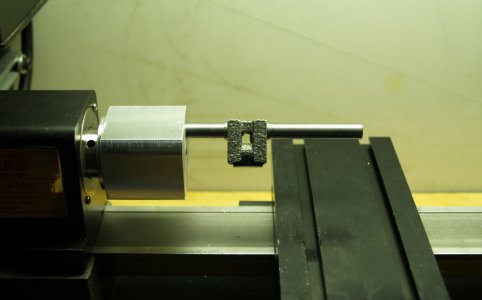

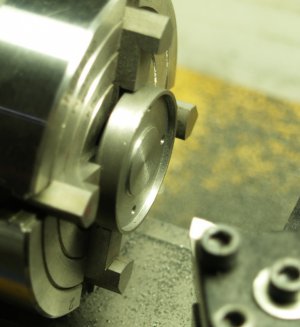

I chose to use a mandrel because no matter how many times I reverse it in the lathe (five times for this part) it's always on center with the previous cut and true to the lathe centers without having to indicate it in.

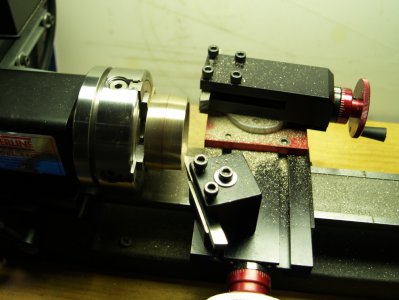

I look at each operation as a puzzle to be solved. I try to figure out the best method to get the results I need with the tools I have. If it takes 15 setups per part than so be it. BTW, I'm using manual Sherline tools without DRO.

I chose to use a mandrel because no matter how many times I reverse it in the lathe (five times for this part) it's always on center with the previous cut and true to the lathe centers without having to indicate it in.

I look at each operation as a puzzle to be solved. I try to figure out the best method to get the results I need with the tools I have. If it takes 15 setups per part than so be it. BTW, I'm using manual Sherline tools without DRO.