Looks like my stand was probably a southbend, the knob on the cabinet door is identical to the rest of the lathe, but either the tray belonged to a something else, or the whole thing was designed for one of the heavy models +. There's a cutout in th cabinet top for a belt, but not in the tray, and the tray lip is too deep for the QC Levers to operate without risers under the feet.

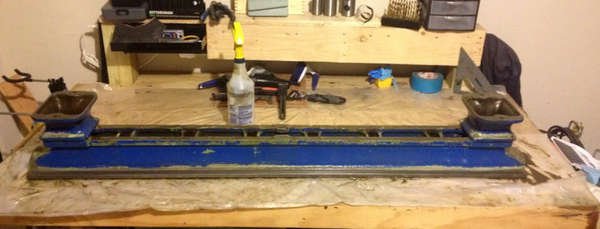

The channel iron these were on isnt very high quality, +-.05 in height variance. I took these to a local job shop to see what they wanted to kiss the tops and bottoms. 2-2.5 hours!! I'm not putting $200.00 into crappy metal, plus I'm pretty sure I can do it on my DP in about the same amount of time. On the + side, I did get a lead on an unadvertised machine tool repair shop that may be able to re-grind my bed. Sounds like one of these old timers who won't take his boots off, and will fix your kids tonka truck on the same invoice he builds your custom spaceship on. Sounds promising.

The other piece goes under the headstock and has an extension welded on the back for the motor mount.

The tops averaged out to about even, so I started with the rails.

Dirty milling attempt in progress. I haven't started in on the tops yet, maybe today. If it gives me too much grief, I'm going to the scrap yard to look for a big hunk of iron. At least I won't mind paying a few bills on a good piece of material.

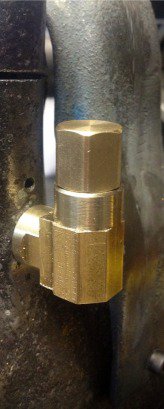

Just as a safety note for those like me who will one day search for evidence that a drill press can be a GOOD substitute for a milling machine. My drill press has a special chuck (Jacobs 33-34c). It has a collar at the top of the taper, that threads onto the spindle and keeps it from coming off until you want it to.

I filled the body with epoxy granite, welded angle iron into the column, and filled it too. It has real column clamps on the column, and the quill, which is 10in long and supports the spindle with 4 tapered roller bearings, and the table is supported at the end by a heavy duty automotive screw jack. It still vibrates like cheap hotel quarter bed if I use cutter bigger than 3/16 or do more than kiss off more than about .02. It's an awesome drill press, and a life saver since I don't have a proper milling machine yet, but it's a sorry substitute for the real thing.

I would not feel safe at all trying anything like this with a standard drill chuck held only by the taper.