So the dealer listed on the serial number card, still has an active address listed with several Industry listings, and I drove over to see if they were still around. Sadly there is a new company there, but still selling industrial machines?? I checked into them, been around since 1992, I wonder if there is any relation to the original tenant. Maybe I'll stop in next week, they have 3000sq/ft of shiny new milling machines and lathes... maybe that's a bad idea.

I got the gear inlays all done. Had to fab (caveman fab) some new arbors to fit them on my polishing machine (cheap drill in a vise). I'll post some more pics of those later tonight.

My little test re-using Citristrip waste went amazing. So much so that the paint fell off before I could get back to video it. I did grab a few seconds of me scraping (more like lifting) off what looks like rubber sheets. Will get the rest of those videos put together later too.

I had 2 shafts in the gearbox that were too wasted to even try to use, the gears had so much play you could hear them clanking around just moving it to a different spot on the bench. Good news is I found a brand spanking new, never used, cone gear shaft for $35.00! Seems like those internal gearbox pieces must either live forever, or get neglected beyond the point of re-sale because its the first one I've seen. He's looking to see what else he has for my lathe, may have hit the jackpot on this one.

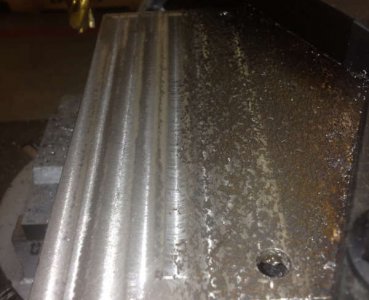

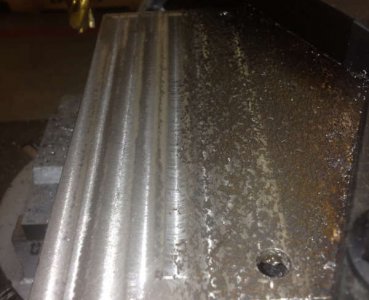

I did spend some time trying to mill the channel iron the bed was mounted on. It's milling OK, but they are so trashed I don't think they are worth working on. There is almost .125" of cup in both of them.

On with the course corrections! I still have the lip on the tray to contend with, the tumbler levers and the lip don't get along unless the lathe has at least 1.5" risers under it, so what's a hobby machinist to do? Make stuff!! I still don't know of a place to get scrap around here, and good iron that size is $$$$ off the shelf, so what's left? I have some precision ground low-carbon 3/8 flat stock that's wide enough, but its not thick enough. I have some pillow stuffing, but I don't think it's rated for this kind of weight. I do have something I've been wanting to try though, and I think I may have found my excuse! I dragged my wife out one weekend a few months back to go problem solving, and thought I found a solution. I went and picked up the stuff today (1 hour total shopping time), and did a trial run, and it looks like a winner!

Epoxy granite using only cheap (<$1/lb finished weight) & readily available local resources (national chains, non-boutique, non-industrial). Not the sort of thing that generates 300 pages of forum fodder, and most certainly not the sort of thing you want to go into production with, but for us... Hobbyists... Maybe? I haven't actually completed a mould yet, but I thought I'd bring you all along for the journey, pass or fail, I'll start a new thread later, and post the link here.