Sweet.

I figured we should start a new thread since this is straying off the 'ease of use' topic, but you keep posting cool stuff and I'm a sucker.

As for the mill, yes. Do all of the above, you won't regret it. CNC control of the spindle is pretty easy. Does your BOB support/have a 0-10v PWM output?

While you're shopping for motors, do yourself a favor and plan on getting an encoder so you can rigid tap... Or at least a spindle index sensor. You can make an index trigger from an inductive sensor (limit switch) and a dumb old chunk of plastic pressed on the top of your spindle like a collar. Use set screws to trigger the sensor, and use 2 or 4 of them for balance. Mach3 can handle multiple index signals, and more is better for tapping.

Basic shopping list for nirvana:

- 1-2HP Motor w/encoder. If you get a really good one that has a 1000:1 constant torque rating you won't need a two-speed belt drive to do low-speed hogging and high-speed small end mills. You can fit an encoder that's WAY cheaper than the one that comes on the BlackMax motor. Really, you can fit a 56C sized motor on top. I managed to get a 182 on mine, but mine's bigger than yours....

If you're worried about 1HP being undersized, don't. Good-quality motors are way under-rated, compared to the grossly-overrated cheap motors. I 'only' have 2HP, but I'd have no problem snapping a 1/2" tap in steel at 500RPM, or running a 3/8 3-flute in aluminum at 7k. Piles of chips, no gear or belt changes.

Here's a peach:

https://www.automationdirect.com/ad...0HP)/Marathon_Black_Max_(0.25HP_to_30HP)/Y535

And another, WITH an encoder already on it:

http://www.ebay.com/itm/Marathon-1h...616518?hash=item282e7cb4c6:g:TRUAAOSw4CFYytt9

- Belt drive. Figure out your top speed, based on your bearings and smallest intended end mill speed. I can go to about 7400RPM before I chicken out, but I expect my bearing to die sooner rather than later, and then I'll replace them with really good ones. If you get an 1800RPM motor, and run it up to 5400RPM with the VFD (max safe RPM on that BlackMax), then a 1:1.3 or 1.4 belt drive should work well to get you to 7500RPM. A single-speed belt drive is way easy to sort out, and the cogged sheaves are pretty cheap and easy to get. You won't regret ditching the gear system, and you might even sell the gear set to someone as a replacement or backup.

- VFD. I got a Hitachi WJ200 and love it. However, the Automation Direct GS-3 VFD's have an optional encoder input card - for a bit more money - that is superb. Takes 3-24VDC complimentary inputs and can work with very high speed encoders. Not something I realized when I bought my Hitachi was that the WJ200 is very limited in the encoder inputs. It's superb otherwise, and can even do positioning (servo-ish). Doing it again, I'd spend the extra $50-100 for the GS-3 VFD just to avoid the encoder input compatibility issues I had to work out.

Even if you don't get an encoder, buy the best-quality motor you can and make sure it has the capability of accepting an encoder later on.

The other option, of course, is to throw down on a servo spindle.

DMM's 1HP, 5kRPM servo:

https://store.dmm-tech.com/products/dst-0-75kw-ac-servo-motor

And the matching drive:

https://store.dmm-tech.com/products/dyn4-h01a2-00-dyn4-ac-servo-drive?variant=20982430342

That combo would be rally, really sweet. Unfortunately, their "big" servos just don't have the top speed I wanted without gearing them up too much and lose low-end torque for big drills and tapping. For you, a 1HP servo would be pretty nice, and you might be able to find one on Fleabay.

Gold Standard:

http://www.ebay.com/itm/Parker-J092...469419?hash=item33ce00786b:g:zfoAAOSw7GRZC3FQ

If you start a new thread "In Search Of the Ultimate G0704 Spindle" I promise I'll chime in.

By the way, I successfully milled Grade 5 titanium for the first time today. I'm still new at this, so it was pretty awesome watching the mill make something round in to a hex. 2750RPM, .625DOC, .025WOC (adaptive), 5.5ipm, .250" 4F. Chips looked good, excuse the never-seize goo.

And yes, I've got an approved Form 1 for those who may be unable to control their urge to chime in about such things.

-S

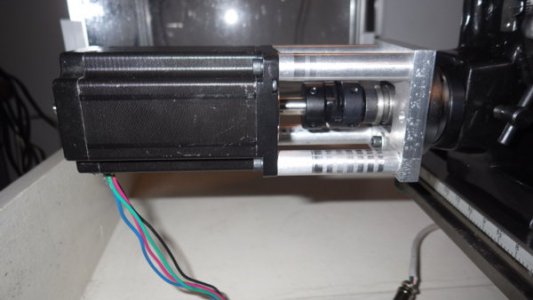

View attachment 233519