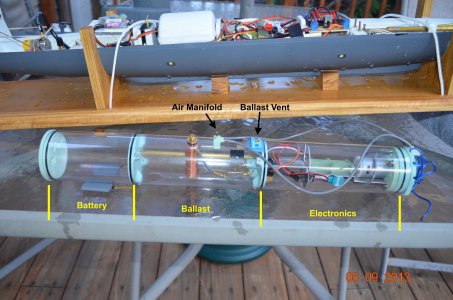

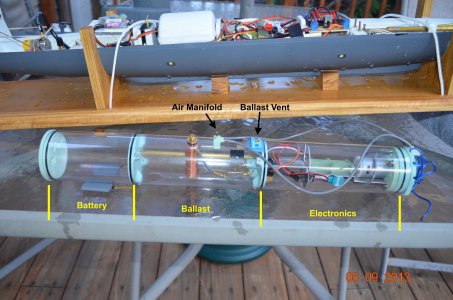

Once the model is built comes the more brain challenging part. In the top of the first pic in the boat you see a bunch of stuff. That was the original container that housed the electronics. It came with the Marlin kit and was impossible to keep water out. It was in the design. The term was coined 'sink-o-matic'. I won't get into it as it was discarded. David Merriman sent me one of his Sub Drivers (SD). This is an acrylic tube with sealed compartments. The center one is the ballast tank and can be flooded with water and also remove the water with air. The forward one held the battery. The aft one is for electronics. The ballast tank is enclosed with bulkheads with o-rings so no water passes the bulkhead. The ends are endcaps also with o-rings. A sealed brass tube connects the battery and electronics compartments to pass wires. As it came from David, it included the drive motor, ballast pump motor and ballast vent servo. More is needed, will describe below.

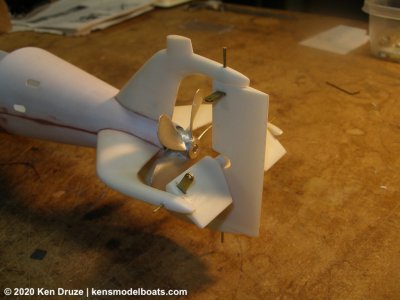

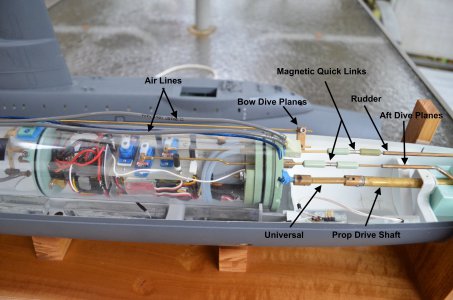

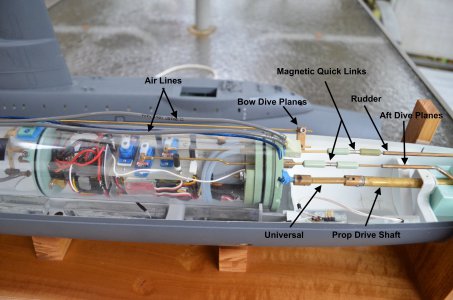

Here are some of the external connections to the SD. The universal is a modified Dumas universal, a common and easy universal drive shaft connection from Dumas Boats. The quick links make easy connections from internal push rods to control surfaces. Another feature designed by David.

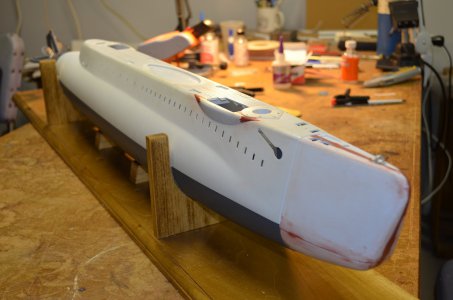

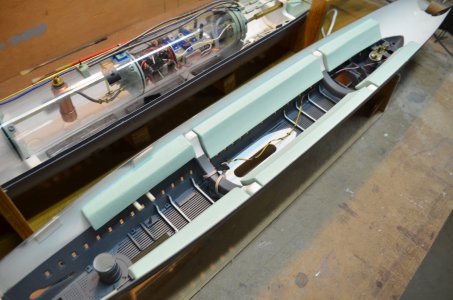

Here the SD is in the boat with all of the connections made. I'm testing in the pool at this point.

Close up of connections.

The push rods from servos and the drive shaft exit the aft bulkhead thru seals, o-rings, to keep water out. There are two brass tubes at the top for air connections.

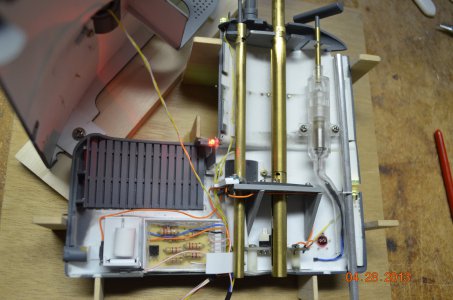

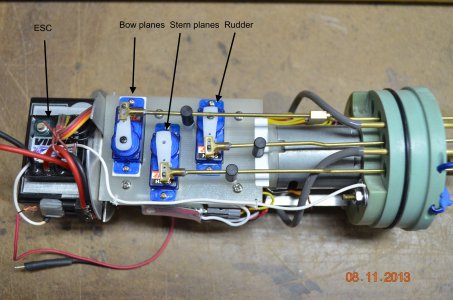

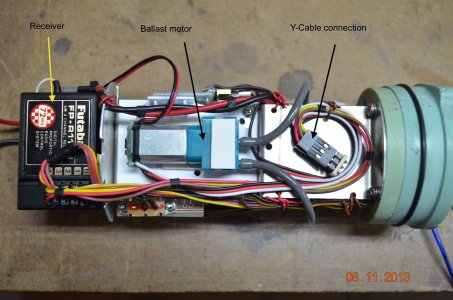

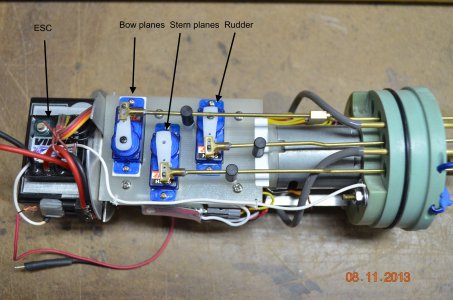

Parts here that do not come with the SD are the motor speed controller and servos. They need to be micro size servos. You can also see the motor, silver can to the right, and air lines above the motor. Like I said, beyond the SD, you need to buy and figure out how these things go together and where to put them. There are forums out there for help if you need help. The push rods from the servos exit thru the bulkhead/o-rings and end in a magnetic quick link.

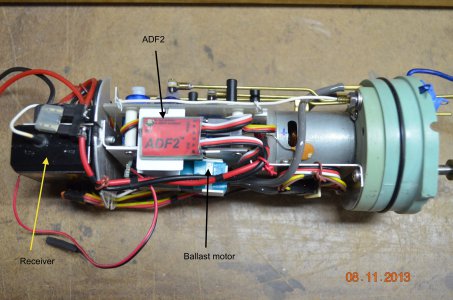

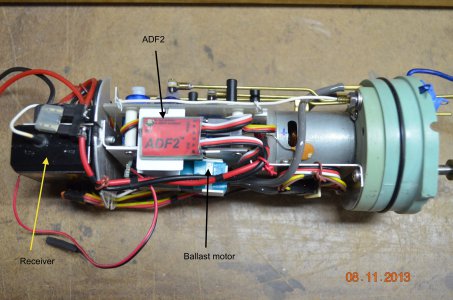

Below the ESC is the radio receiver. The air lines connect to the ballast motor. The ADF2 does a number of things. Mainly it is a pitch controller. It connects between the receiver and servo for the aft dive planes. As the model is running submerged, it detects the the fore and aft pitch of the model and sends signals to the aft plane servo to adjust the dive planes to keep the boat absolutely level. When on the bench out of the water, if you lifted the bow of the boat, the pitch controller detects this movement and it will send a signal to the aft dive planes to move until the boat is level.

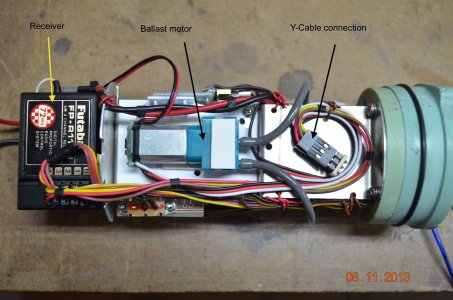

Here you see the radio receiver with all of the servo connections. The ballast motor has air line connections. When you want to surface the boat, the ballast tank will be full, you move the transmitter stick which signals the receiver, it closes the ballast vent and activates the ballast motor which sends air into the ballast tank evacuating the water. The ballast motor and ballast vent share one channel on the radio system. The servo and motor are connected to the receiver with the y-cable connection. To submerge the boat, the ADF2 signals the ballast servo to open the ballast vent and allow water to fill the ballast tank. Again, you have to buy all these things and put them together. There are other manufacturers of some of these devices like the ADF2. Those is Europe probably have their own items they use there.

There are other ways to setup model submarines. With this method the hull is free flooding with water. Water is kept out of the SD to keep the electronics and battery dry.