Last post hopefully on the Miss Belmar. Here are some detail pictures with explanations.

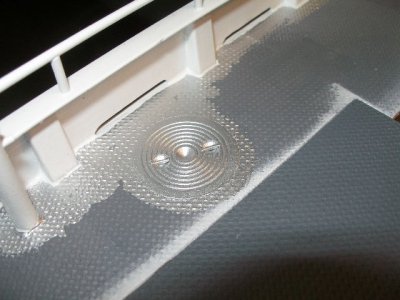

Here you can see the unpainted diamond plate deck and deck plate. Also the brass railings and the anchor windlass. The brass is from K&S metals. The railings are 3/32 brass tubing. Each junction has a 1/16 brass pin to help solidify the joint when it gets soldered. The anchor windlass, the squarish thing in the middle, is a bunch of sheet brass also soldered. That was difficult to solder with the many facets. The round rollers on each side were made on a lathe and they do spin. The two posts nearer the front of the picture are tubes that the anchor line would go down to the rope locker. I planned on making a winch so the anchor would drop sand raise but never did. It would be for display only as dropping an anchor in could foul in weeds which would be hard to clear.

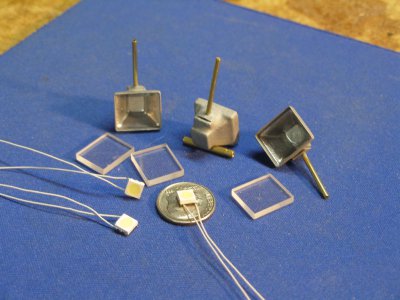

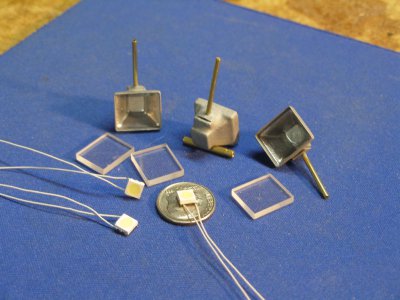

In order to make the floodlights on the upper deck I had to come up a way to make them. This device is a vacuum forming fixture. The vacuum is connected on the right. Styrene is heated in the over then dropped on the perforated platform and sucked into shape.

These are the lights made with the vacuum form above. Had to cut & file acrylic for a lens. Solder surface mount wires to the LED's. And a brass post to the styrene as a mount point. You can see the LED's in previous pictures I posted.

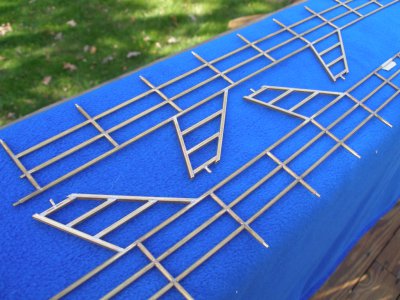

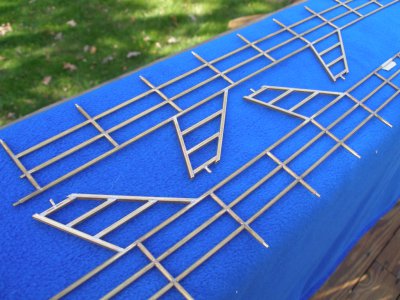

These are the unpainted brass railings on the upper deck. Again each joint is pinned and soldered.

This is the mast on top of the pilot house. It was cut by a friend on his Bridgeport CNC machine. He recently passed away, sad. He was master machinist by trade and had his own business until he retired.

Float test in the pool. The hull is just about done at this point. The cabin/pilot house still has not been updated and is in the old colors.