I am going to skip ahead to part E under Miscellaneous which is installing Oil Drain Stopcocks. I don’t have access to the information I need for the three short sections preceding this so I thought I would continue to move forward and then circle back around to do these skipped topics later.

V. Miscellaneous

E. Oil Drain Stopcocks- I have had the lathe for almost a year now and noticed a while ago that the original oil in the site gauge was getting dirty, so I decided to change the headstock oil and also the oil in the apron gearbox while I was at it. The PM Manual suggests that to do this for the headstock gearbox you should remove the cover, take off the change gears, hold a paper channnel in place, remove the drain plug and let the oil run down the channel into a bucket on a stool. For the apron, it is a bit less involved and one is instructed to simply remove the drain plug, let the oil drain and then refill. I guess the oil is to go into a shallow pan and then caried away to where you dispose of your waste oil. Not a big deal for either but I thought I would try to make it a bit easier and less messy so I would be more likely to change the oil regularly.

This is how I changed the headstock oil the first time. The pipe is a bit of an improvement over holding a paper channel against the side of the gearbox while the oil drains but you can still see dirty oil pretty much everywhere:

I think it is an easier and cleaner process after the Stopcocks are installed:

.

The Headstock Oil Drain Stopcock- First of all, be careful of the threads. Like the coolant guard there are British, not metric, threads here. The drain plug is 3/8”-19 BSPT(aka R3/8-19) so at some point an adapter is need if you are going to go to US standard pipe thread such NPT or NPTF.

Here is the kit view of what you will need to start this job and a view of the location of the drain with the external change gears removed:

.

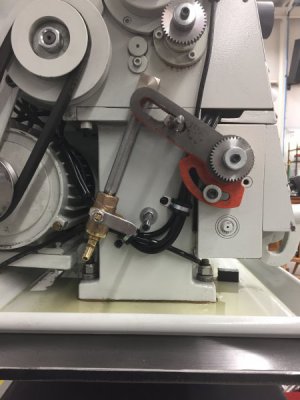

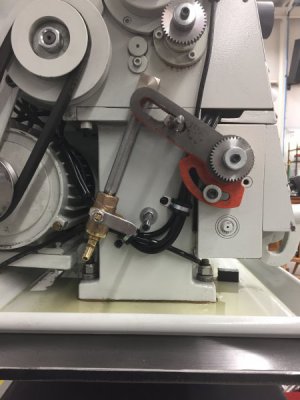

The first thing to attach is the 90 degree elbow(3/8” BSPP F x BSPT M, MC 4860K428). There is a very tight clearance here, in fact, I needed to reduce the diameter of the thread a bIt( I used a compressed die and re-threaded) to get the elbow to go in far enough that it would not hit the orange arm on the lathe:

.

.

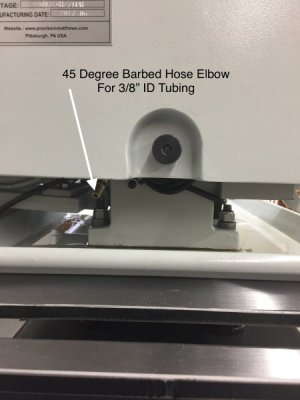

Next, I attached a 6” stainless pipe(3/8” BSPT x 3/8” NPT, MC 2427K333), 3/8” NPT bronze shut-off valve(Canbraco(Appollo)78-250-10) and 45 degree 3/8” NPTF barbed fitting for a 3/8” ID drain hose(MC 53525K48). I shortened the stainless handle so it would not hit the post that holds the cover. I used pipe sealant on all joints:

I removed one of the feet on the valve, drilled the remaining foot out to 1/4”, drilled and tapped the lathe base to 1/4”-20 and fastened the valve with a socket head cap screw and 1” nylon stand-off:

.

.

This set-up allows me to easily drain the oil without taking the cover off which is especially nice for me since I have the headstock handwheel that I would need to remove first:

.

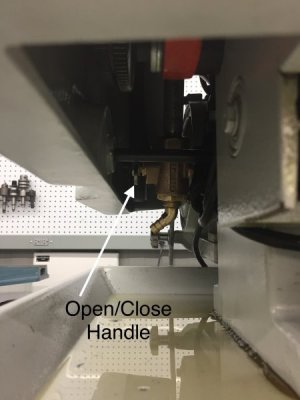

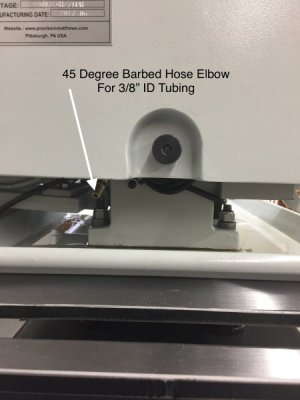

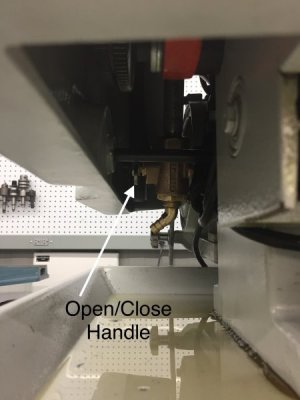

The valve on the apron gear box was also pretty straightforward. I removed th M8 x 1.25 drain plug screw, drilled it out to 7/16” using a short drill bit and an angle drill. I then tapped it to 1/4-18 NPT. I then put in a stainless 1/4” NPT 90 degree adapter(MC 4452K472) and a 1/4” NPT on/off valve(MC 8179K74) with a hose barb for 3/8” ID tubing(like the headstock drain):

.

.

That’s it.