IV). Miscellaneous

A. Headstock Handwheel- this addition to the P 1236-T has been very useful. I use it frequently, for example, when I am changing gears to help the gears mesh, when I am moving the chuck repeatedly when centering a work piece in the 4JC and, although it is probably considered bad practice, I use my hand on the handwheel to slow down the lathe at the end of an operation. For me, it is better than doing these things by grabbing the chuck. Although this is a pretty straightforward project it took me quite a while; it would be nice if PM had this as an option.

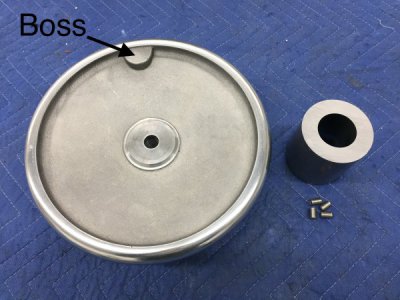

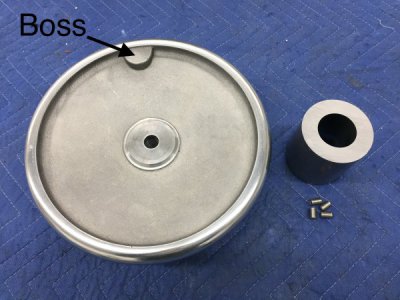

For this project I took a 10” aluminum wheel and balanced it, bored it out to match the ID of my spindle bore and then attached it to the spindle with an adapter sleeve. I attached the adapter with set screws on the spindle side and a shrink fit on the wheel side. The kit view below is deceptively simple; this project took me most of a weekend but I do like the result.

The Wheel- I ordered several wheels from McMaster-Carr; the one that looked the best was a 10” spokeless aluminum handwheel with a 5/8” unthreaded through hole and 2-1/4” OD hub(MC 8515K53). Unfortunately, all wheels from MC that I considered have a boss on them for attaching a handle, I would guess. I was concerned that this would cause the wheel to be unbalanced and cause vibration on the lathe. I put the wheel on a bicycle wheel balancer and not surprisingly found it to be unbalanced To balance the wheel I drilled out the boss, checked it on the balancer, drilled out more and rechecked it until the wheel was balanced.

.

.

Each piece of tape marks where the wheel stopped. The random arrangement indicates it is balanced. I put it on a hand drill to test for balance.

.

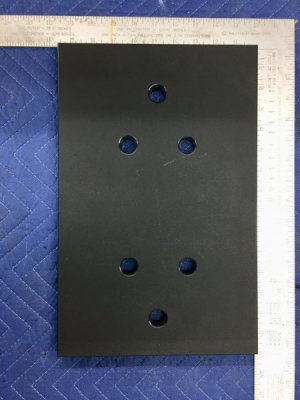

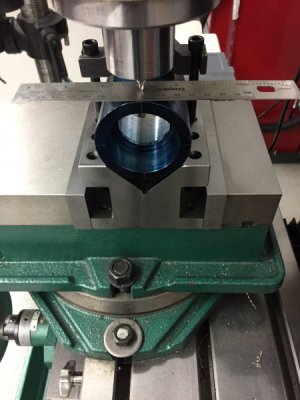

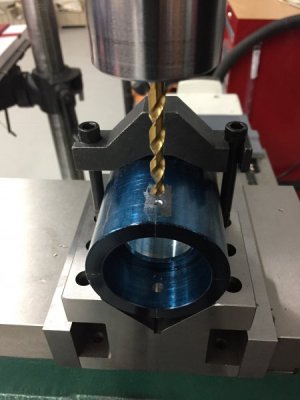

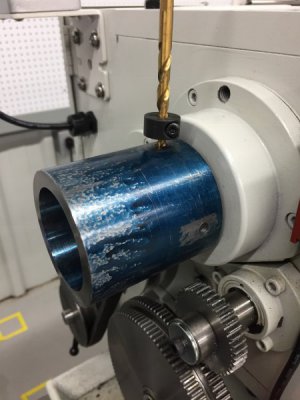

Next I drilled, then bored the through hole of the wheel to match the diameter of the spindle bore. I didn’t want to lose any of the generous 1-9/16” spindle bore of the 1236-T.

.

.

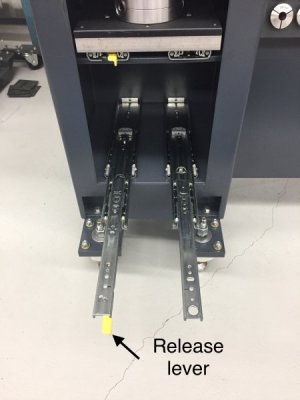

Next, I enlarged the hole in the lathe cover. The hole on the cover was eccentric and too small to accept the adapter collar that I was planning on making next so I enlarged the hole using a spindle sander.

.

.

So that finishes the modifications of the wheel, next is making the adapter sleeve.

Since I am still a bit concerned about losing the post due to the website problems I am going to post this and then go on to making the adapter sleeve in the next post.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.