It’s not only the radial eccentricity that is the issue, it’s also the axial. Every bearing is a very rigid spring, and the stiffness of the spring determines how rigid the system is. With potentially larger variation in rolling element size as well as runout with the standard bearings, you have less contact between the inner and outer races, so that means your spindle is less stiff than one where more rolling elements are in full contact. You also have a limit to how much preload you can put on a rolling element before it overheats. When the load is spread among more rolling elements, you can have a higher preload and thus more rigidity. As a thought experiment, consider a situation where one rolling element is maximum size and all others are minimum, all the load goes through one or two rolling elements and you can only preload the bearing up to the limit of those elements. Now consider all the rolling elements and races are perfectly the same, the load gets spread evenly between all of them, so your preload can be higher, and the stiffness is higher. A real bearing is somewhere in-between those two examples, and a higher precision bearing puts you closer to the perfect situation.

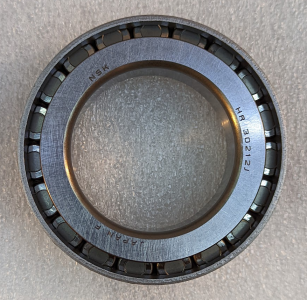

Having a P5 bearing at the chuck end helps a lot, but not having one at the outboard end could be an issue, or you might get lucky and that bearing has low variation and you don’t see a difference. I see this as a weak link in the chain. This could show up as chatter or poor finishes on your workpiece, or ability to take deeper cuts. What some people blame on the compound might also be poor stiffness of the spindle due to bearing choices. What it looks like Grizzly is doing is playing the odds that the standard precision bearing doesn’t cause issues significant enough to affect sales, and they can get away with just one high precision bearing to save costs. But, based on Cadillac’s experience, it doesn’t look like they are not even using P5 any longer since the bearings they shipped him were standard precision. If you opened the bearings, I would be curious to see if they are standard or high precision, the price indicates they are standard.

Having said all that, FAG X-Life bearings have some tolerances to P6 and would likely be better than standard precision if cost is an issue. They cost about the same as standard precision, but you get a better tolerance quality overall.

Having a P5 bearing at the chuck end helps a lot, but not having one at the outboard end could be an issue, or you might get lucky and that bearing has low variation and you don’t see a difference. I see this as a weak link in the chain. This could show up as chatter or poor finishes on your workpiece, or ability to take deeper cuts. What some people blame on the compound might also be poor stiffness of the spindle due to bearing choices. What it looks like Grizzly is doing is playing the odds that the standard precision bearing doesn’t cause issues significant enough to affect sales, and they can get away with just one high precision bearing to save costs. But, based on Cadillac’s experience, it doesn’t look like they are not even using P5 any longer since the bearings they shipped him were standard precision. If you opened the bearings, I would be curious to see if they are standard or high precision, the price indicates they are standard.

Having said all that, FAG X-Life bearings have some tolerances to P6 and would likely be better than standard precision if cost is an issue. They cost about the same as standard precision, but you get a better tolerance quality overall.