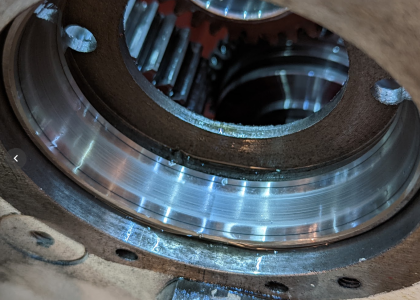

Replacing the spindle bearings on my lathe was more of a task than I expected. Biggest problem for me was finding genuine bearings in a p5 at a reasonable price. Local distributor could get them for both around 700.00. The bearings grizzly sells are not p5 bearings they are a standard j class that you can go buy at Napa for 30 dollars a piece.

Every video I’ve seen including the video above they are replacing with a standard bearing and claim to get good results. the above video he mentions about the actual bearing from grizzly not having the p5 rating on the races.

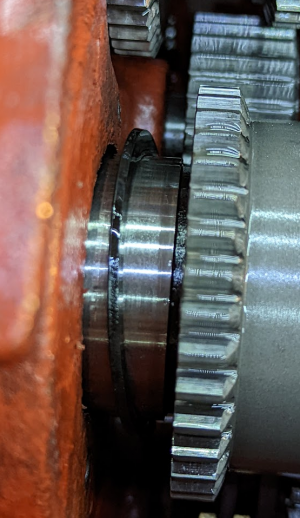

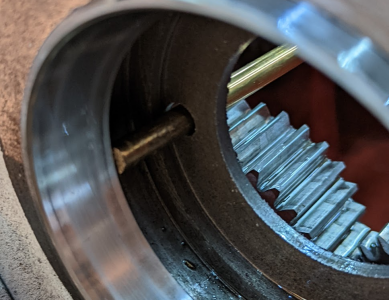

After a lot of hassle I eventually found both bearings 30212 and 30210 in a p5 rating. They are KLF-ZVL made in the Czech Republic. I found a seller on eBay and for both they were 250. I purchased FAG brand from a seller and they couldn’t deliver on it and eventually refunded my money because they couldn’t get them.

I haven’t finished the spindle as of yet. Life has had me busy to get the time I need. Not something I want to rush. I will update my bearing post with my results.

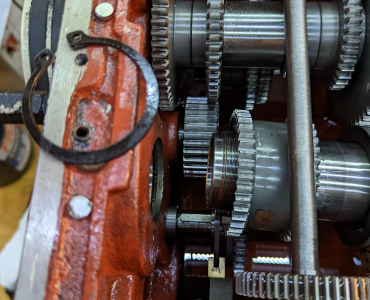

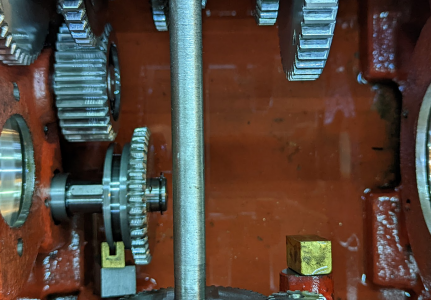

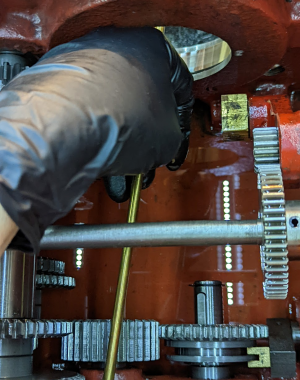

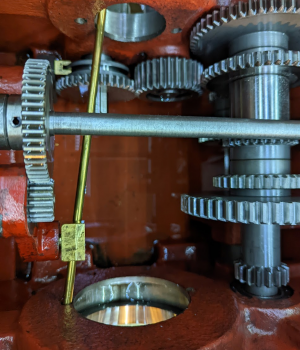

When I first purchased my lathe I put magnets on the inside of the headstock in three different places. I put quarter size ones on the bottom to catch sediment. Then little rectangle ones in the channels front and back of the holes that supply the headstock bearings. When I recently opened the headstock for the bearing replacement the magnets on the bottom had a film of real fine metal particle covering them. The little ones in the channels had a miner amount so they are definately doing their job. I’d recommend magnets. I did wonder about the effects of magnets on the casting with bearing and if it causes a problem. Idk I tried to keep away from the bearings.

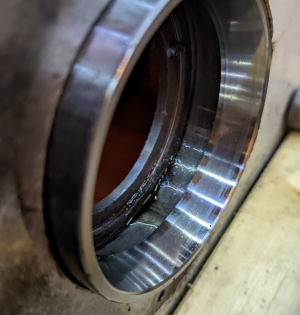

I also didn’t like how the drain plug was for draining the oil. I found a petcock drain style that’s used on small engines. I believe the thread is m16x1.5. I have it installed but haven’t needed to use yet time will tell. Here’s acouple pics of the bearings I did find and the drain valve.

Every video I’ve seen including the video above they are replacing with a standard bearing and claim to get good results. the above video he mentions about the actual bearing from grizzly not having the p5 rating on the races.

After a lot of hassle I eventually found both bearings 30212 and 30210 in a p5 rating. They are KLF-ZVL made in the Czech Republic. I found a seller on eBay and for both they were 250. I purchased FAG brand from a seller and they couldn’t deliver on it and eventually refunded my money because they couldn’t get them.

I haven’t finished the spindle as of yet. Life has had me busy to get the time I need. Not something I want to rush. I will update my bearing post with my results.

When I first purchased my lathe I put magnets on the inside of the headstock in three different places. I put quarter size ones on the bottom to catch sediment. Then little rectangle ones in the channels front and back of the holes that supply the headstock bearings. When I recently opened the headstock for the bearing replacement the magnets on the bottom had a film of real fine metal particle covering them. The little ones in the channels had a miner amount so they are definately doing their job. I’d recommend magnets. I did wonder about the effects of magnets on the casting with bearing and if it causes a problem. Idk I tried to keep away from the bearings.

I also didn’t like how the drain plug was for draining the oil. I found a petcock drain style that’s used on small engines. I believe the thread is m16x1.5. I have it installed but haven’t needed to use yet time will tell. Here’s acouple pics of the bearings I did find and the drain valve.