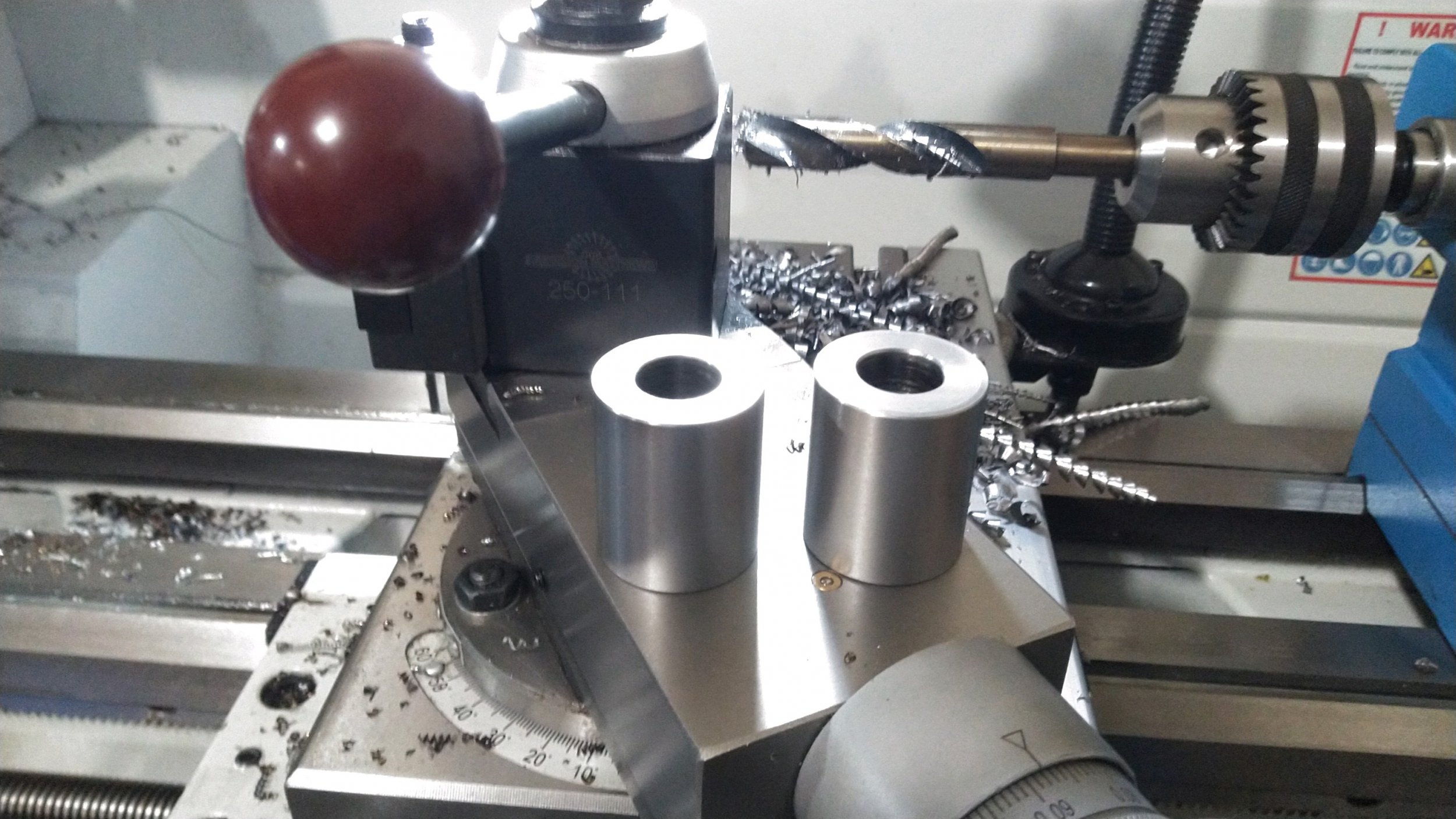

Do as said above by the others. Get the setup done on the lathe. My 1130 had a tendency to leave spiral marks when I got it first set up and I was very concerned. Turned out after I did like the guys have said and adjusted the rear saddle gib all was better. The tool grind in HSS needs to be decent to get good finish. Just as a teaser here is a picture of what the machine can do. Carbide tool, .040 DOC , .005 feed, about 875 RPM as best as I remember. I usually do use HSS ground like the ones in Mikey's thread on HSS tools.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

Problems with first steel cut on 1130v lathe

- Thread starter rronald

- Start date