- Joined

- Feb 8, 2014

- Messages

- 11,176

So the main drive roller needs a way to drive it. Both for machining and in operation. I could have keyed it and used set screws to secure it to the shaft, but I really hate set screws and keys. They don't hold well and in start stop (or reversing) application they have a tendency to wear and get loose. You can actually transmit more power with a clamp.

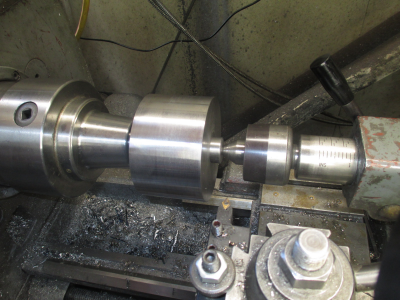

The main shaft is 1 inch, so add a 1 inch shaft collar. This will be the only drive interface with the roller. Those are 10-24 screws, I would have used two 1/4 inch screws, but the wall of the clamp is a bit skinny for 1/4 inch. The shear load that those 4 screws will take far exceeds the torque that the motor is capable of producing.

I set this up in my 5C fixture on the shaft that it will be installed on.

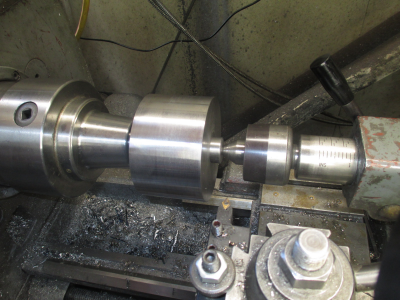

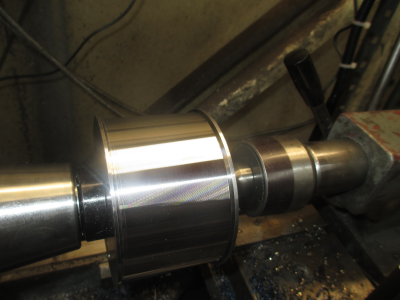

Then over to the lathe for final finishing. Still using the same shaft as an arbor.

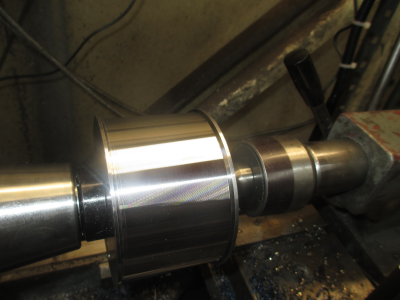

And done. 8620 is a pleasure to machine.

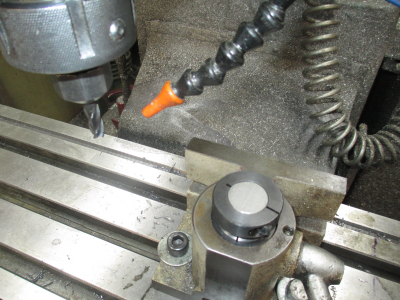

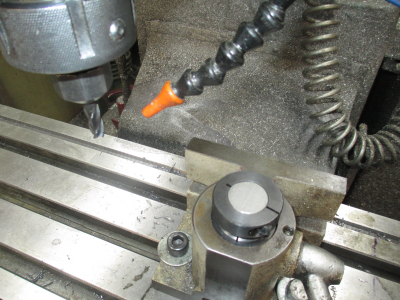

Then for the next piece, I need to modify another shaft collar to be a cam for the On/Off switch. I used a shaft collar because I want it to be easily adjustable. So set it up in the 5C collet fixture.

And done. Took about 10 minutes.

And the last bit for today, drill and countersink the attaching holes in the swing arm bushing.

Tomorrow I'll cross drill the swing arm shaft, turn a little button for the spring pressure screw, and design & turn the adapter shaft for the VFD speed pot. That should finish up all of the machined parts for this project unless I forgot something. There will most likely be some machining on assembly just to get a final fit.

I'm going to try to get the frame welded up and painted this weekend also.

Stay tuned......

The main shaft is 1 inch, so add a 1 inch shaft collar. This will be the only drive interface with the roller. Those are 10-24 screws, I would have used two 1/4 inch screws, but the wall of the clamp is a bit skinny for 1/4 inch. The shear load that those 4 screws will take far exceeds the torque that the motor is capable of producing.

I set this up in my 5C fixture on the shaft that it will be installed on.

Then over to the lathe for final finishing. Still using the same shaft as an arbor.

And done. 8620 is a pleasure to machine.

Then for the next piece, I need to modify another shaft collar to be a cam for the On/Off switch. I used a shaft collar because I want it to be easily adjustable. So set it up in the 5C collet fixture.

And done. Took about 10 minutes.

And the last bit for today, drill and countersink the attaching holes in the swing arm bushing.

Tomorrow I'll cross drill the swing arm shaft, turn a little button for the spring pressure screw, and design & turn the adapter shaft for the VFD speed pot. That should finish up all of the machined parts for this project unless I forgot something. There will most likely be some machining on assembly just to get a final fit.

I'm going to try to get the frame welded up and painted this weekend also.

Stay tuned......

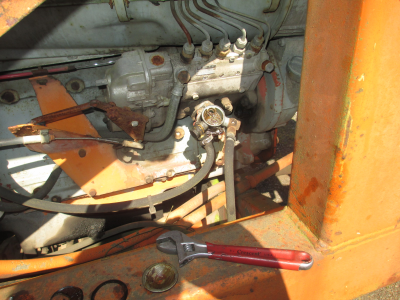

And sitting right in front of the shop door, which was a blessing and a curse. I either had to fix it or drag it out of there. Since it is a nice day to work out side, and right in front of the shop, I figured it would be a good time to fix it.

And sitting right in front of the shop door, which was a blessing and a curse. I either had to fix it or drag it out of there. Since it is a nice day to work out side, and right in front of the shop, I figured it would be a good time to fix it.

But I did fish around in there and could not find a thing. I think I will drain the tank and put fresh fuel in it before I use it again.

But I did fish around in there and could not find a thing. I think I will drain the tank and put fresh fuel in it before I use it again.