-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM’s new MagXact MX-200L DRO?

- Thread starter Jake P

- Start date

I don't understand how that could be. A 1/2" end mill and a 1" end mill can both travel though material at 20 ipm. If you have a 1" end mill and are only using half of it to cut a 1/2 step into a block the feed rate isn't suddenly changed.Feed rates are absolutely related to cutter size. Feed rate is not table movement but is cutter movement through material.

Unless the feed rate display is actually calculating something different than what I consider feed rate, which is just the table speed.

Edit: I think I understand now. It probably is reading cutter feed rate as opposed to table feed rate. That may be why PM said it doesn't read out feed rates when I asked. Does the DRO allow you to store tool diameters that adjusts the cutter feed rate based on their diameters?

Last edited:

I am probably doing a horrible job at describing this (again I am a total noob) but the way I understand feed rate, is the speed at which the cutting edge moves through material in Surface Feet per Minute. I do hope someone chimes in on this and clarifies one way or another.

Why does my table only move 6.5" in a minute when it reads 20 when unit of measure is inches, and at the same power feed setting changes to 8 when I change unit of measure to mm?No, it is just table movement/time, not a SFM calculation. You can set it to read a specific axis. I have an EL700, the feed rate is quite helpful.

I will do so, but either way if it is only measuring table distance over time, the number when switched to mm should go up...unless it is measuring mm/sec.

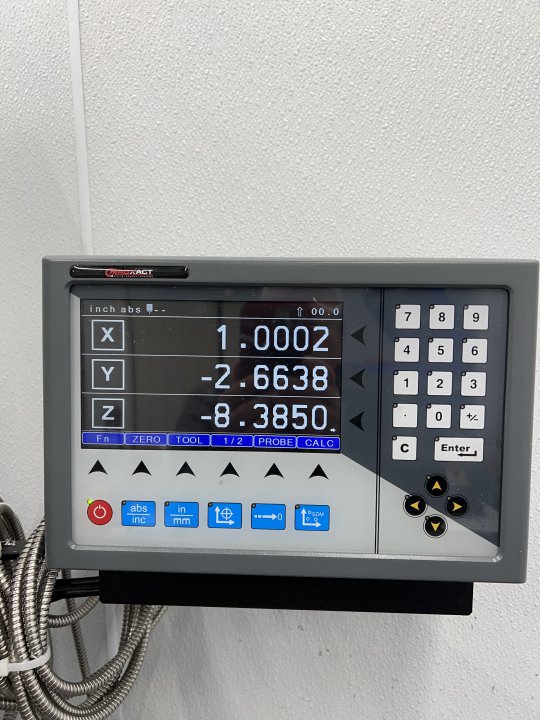

Here's a very inaccurate representation of my DRO readings. The axis was zeroed on the 0 of the ruler, and then the table was moved.

I am not sure Lucas. I'm a total noob, and from what Mark is saying it should only be displaying table movement. What is weird is:Edit: I think I understand now. It probably is reading cutter feed rate as opposed to table feed rate. That may be why PM said it doesn't read out feed rates when I asked. Does the DRO allow you to store tool diameters that adjusts the cutter feed rate based on their diameters?

In inch settings, it is displaying a rate that is spot on with what I would see as SF/m with a 1 " cutter at 60 RPM's, making it VERY easy to dial in a speed and feed based on any imperial sized cutter I could choose with some simple math.

In mm settings, it is displaying a rate that is spot on with what I would see as SF/m with a 10mm cutter spinning at 60 RPM's, making it VERY easy to dial in a speed and feed based on any metric sized cutter I could choose with some simple math.

Not sure if it is blind luck here, but that is what I am seeing on my DX-200.

Edit - I really don't think I am thinking about this correctly...but I am at a loss as to why my DRO is showing 20 and the table is only moving 6.5".

Last edited:

I checked mine, at 10 IPM it travels 10" in 1 minute, and 254 mm. The display for feed rate in metric shows ~4.2 mm/sec. 254/60 = 4.23.

Corrected to IPM. Always seem to have issues with my computer changing things, or maybe it is just my old brain playing tricks on me.

Corrected to IPM. Always seem to have issues with my computer changing things, or maybe it is just my old brain playing tricks on me.

Last edited: