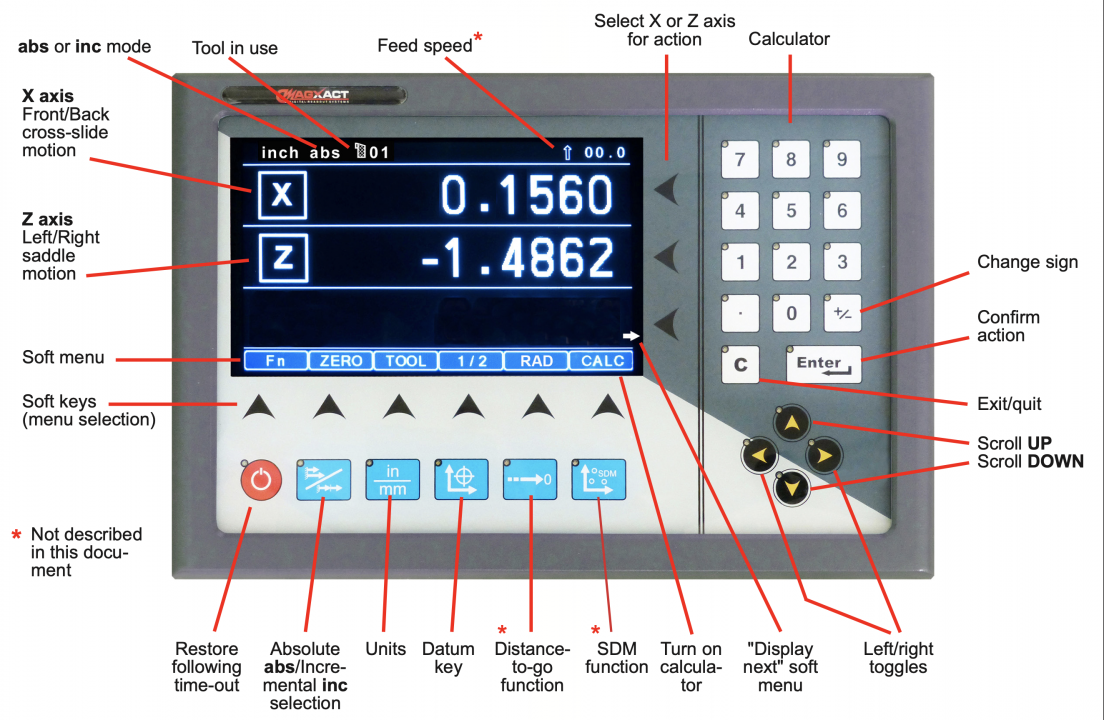

Well that's frustrating. I had heard they did, but wanted to confirm from Precision Matthews as that's what I was planning on ordering. When they said it didn't I didn't see any reason to spend the extra for the MX200 so I ordered an MX100 for my lathe.I can confirm that it DOES display feed rate in upper right corner.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM’s new MagXact MX-200L DRO?

- Thread starter Jake P

- Start date

Call them back. PM me your phone number and I would be happy to send a videoWell that's frustrating. I had heard they did, but wanted to confirm from Precision Matthews as that's what I was planning on ordering. When they said it didn't I didn't see any reason to spend the extra for the MX200 so I ordered an MX100 for my lathe.

From their website.

Does it read out in inches/min or mm/min? Or is it switchable between the two?From their website.

View attachment 394907

It looks like It does both inches and meters? The number goes down when I change from inches to mm.Does it read out in inches/min or mm/min? Or is it switchable between the two?

I tested the feed at 20 for 1 minute and the table moved 6.5 inches roughly, so it appears it is calculating SFM on a 1 inch cutter.

When I change to mm setting the feed value changes to about 8 so it SEEMS like it is basing SFM on a 1 cm cutter.

I know it does change based on in/mm toggle, I am just unsure on exacts.

Caviat, I know once RPM is added to what I just said above, it is like I don't even know what I am talking about, so I THINK some more math needs to be incorporated into determining feed rate, I am a new hobby machinist so I am still learning here. Logic would tell me that that number would be based on 60 RPMs?

Here is a more in depth manual for what I think is the OEM DRO, Electronica 750.

Does the feed rate change when changing RPM of the spindle, but keeping the axis feed constant? Is it calculating some sort of chip load?It looks like It does both inches and meters? The number goes down when I change from inches to mm.

I tested the feed at 20 for 1 minute and the table moved 6.5 inches roughly, so it appears it is calculating SFM on a 1 inch cutter.

When I change to mm setting the feed value changes to about 8 so it SEEMS like it is basing SFM on a 1 cm cutter.

I know it does change based on in/mm toggle, I am just unsure on exacts.

Caviat, I know once RPM is added to what I just said above, it is like I don't even know what I am talking about, so I THINK some more math needs to be incorporated into determining feed rate, I am a new hobby machinist so I am still learning here. Logic would tell me that that number would be based on 60 RPMs?

That is weird that it goes from 6.5 to 8 when changing from inches to mm. That doesn't seem to be a direct conversion from inches to mm or cm.

the table feeds about 6.5" linear when the SFM is listed as 20 in the inch setting. A 1" cutter times Pi times 6.5" is roughly 20.

when I change to metric, the SFM drops to about 8, If I am right, the SFM is now being tallied up based on a 1 CM cutter. 20 divided by 2.54 is about 8.

Everything above is based on 60 RPM

Edit - The feed rate DOES NOT change based on RPM. The 2 are not linked. That is why math needs to be performed to determine actual SFM based on RPM's and size of cutter. I have not done any deep diving into setting tool diameters, and presetting RPM values into the DRO based on saved tools, but I imagine that quick math would need to be performed for each operation.

IOW - If using a 2.5" cutter, at 600 RPM, IF the DRO was displaying 20 IPM you would need to multiply like this

20 x 2.5 (for the cutter) x 10 (for 10 x 60 RPM) for an actual SFM of 500,

Like I said, I am new to this but the numbers I think are generated by only the 2 values the DRO could possibly know, table travel and a standardized sized cutter, and then bases that on 60RPMs to make the math easier for us.

when I change to metric, the SFM drops to about 8, If I am right, the SFM is now being tallied up based on a 1 CM cutter. 20 divided by 2.54 is about 8.

Everything above is based on 60 RPM

Edit - The feed rate DOES NOT change based on RPM. The 2 are not linked. That is why math needs to be performed to determine actual SFM based on RPM's and size of cutter. I have not done any deep diving into setting tool diameters, and presetting RPM values into the DRO based on saved tools, but I imagine that quick math would need to be performed for each operation.

IOW - If using a 2.5" cutter, at 600 RPM, IF the DRO was displaying 20 IPM you would need to multiply like this

20 x 2.5 (for the cutter) x 10 (for 10 x 60 RPM) for an actual SFM of 500,

Like I said, I am new to this but the numbers I think are generated by only the 2 values the DRO could possibly know, table travel and a standardized sized cutter, and then bases that on 60RPMs to make the math easier for us.

Last edited:

I don't think the cutter size should have anything to do with it. If it's reading out at 20 inches per minute, and then switches to about 8cm/min when you switch to metric that seems to me working correctly. The bigger issue is why is it reading 20 inches per minute when the table is really moving at Roughly 6.5 ipm? I wonder if there's a setting that needs to be changed to get it to read correctly.the table feeds about 6.5" linear when the SFM is listed as 20 in the inch setting. A 1" cutter times Pi times 6.5" is roughly 20.

when I change to metric, the SFM drops to about 8, If I am right, the SFM is now being tallied up based on a 1 CM cutter. 20 divided by 2.54 is about 8.

Everything above is based on 60 RPM

Edit - The feed rate DOES NOT change based on RPM. The 2 are not linked. That is why math needs to be performed to determine actual SFM based on RPM's and size of cutter. I have not done any deep diving into setting tool diameters, and presetting RPM values into the DRO based on saved tools, but I imagine that quick math would need to be performed for each operation.

IOW - If using a 2.5" cutter, at 600 RPM, IF the DRO was displaying 20 IPM you would need to multiply like this

20 x 2.5 (for the cutter) x 10 (for 10 x 60 RPM) for an actual SFM of 500,

Like I said, I am new to this but the numbers I think are generated by only the 2 values the DRO could possibly know, table travel and a standardized sized cutter, and then bases that on 60RPMs to make the math easier for us.

Or if it just doesn't work very good which is why drop pros and precision Matthews don't discuss it much in the manual.

FYI I think DRO pros and precision Matthews are both just resellers of electronica DROs. I suspect PM just chose a model with all soft touch buttons where the manufacturer makes stand alone buttons for the number keypad on the DRO pros version.

Feed rates are absolutely related to cutter size. Feed rate is not table movement but is cutter movement through material.I don't think the cutter size should have anything to do with it. If it's reading out at 20 inches per minute, and then switches to about 8mm/min when you switch to metric that seems to me working correctly. The bigger issue is why is it reading 20 inches per minute when the table is really moving at Roughly 6.5 ipm. I wonder if there's a setting that needs to be changed to get it to read correctly.