-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm 1228-vf-lb Lathe Preparations

- Thread starter Franko

- Start date

- Joined

- May 14, 2015

- Messages

- 179

So, the feed direction is a change gear operation? I really wish I'd known how funky & limited the control layout for the apron is; I'd have gone for the 1127 instead. The typo(s) and translation in the instructions for change gears make it extremely unclear, but I'm guessing we are to rotate the upper banjo for this maneuver, and the lower to accomodate the threading gears. Since there's only two positions for the upper, I wonder if a push-pin setup could work for much faster tool-free change over? Maybe even a latching lever that sticks out the front of the door?

Last edited:

- Joined

- May 14, 2015

- Messages

- 179

Franko, do you hear any noise at all from the spindle while it is running? I can hear a quiet, unmuffled (i.e. outside the headstock) 'brushing,' sort of like a soft material against a smooth surface, while in operation. I'm guessing it is the outer bearing seal, which I'm only hearing since the gearbox is almost comically silent while running, and not something ominous (a 200lb box was bouncing off the top of the chuck/spindle on the drive down once the crate collapsed, after all).

- Joined

- Aug 12, 2013

- Messages

- 858

I don't really see that as much of a limitation. I very seldom feed left to right, and I have never fed back to front while cutting. When resetting from a cut, it is always quicker to use the hand wheel to get the carriage (or cross slide) back to the starting position.So, the feed direction is a change gear operation?

Until you get to a 12x lathe with a Norton QCGB, lathes tend to have very limited functions in their QCGB, and many feed changes and almost all threading involves swapping change gears.

- Joined

- Feb 24, 2015

- Messages

- 1,382

I don't hear any noises that sound wrong on mine. It runs very smooth and quiet compared to my old lathe.

I agree with Tim about the feed reversal. It doesn't seem like an issue to worry about to me.

The 1127 has a feed direction lever, but it only accommodates two speeds. For more, you have to change gears.

With only one selector lever on the QCGB, it looks to me like there would be a lot more gear changes required under the lid of the 1127.

I agree with Tim about the feed reversal. It doesn't seem like an issue to worry about to me.

The 1127 has a feed direction lever, but it only accommodates two speeds. For more, you have to change gears.

With only one selector lever on the QCGB, it looks to me like there would be a lot more gear changes required under the lid of the 1127.

Last edited:

- Joined

- May 14, 2015

- Messages

- 179

"Until you get to a 12x lathe with a Norton QCGB, lathes tend to have very limited functions in their QCGB, and many feed changes and almost all threading involves swapping change gears."

Yeah, I know, but that's the size I learned on, and I am adverse to change . Nah, I was really hoping to essentially get a 12x36 with a short bed in the 1228, and for the most part that's true, with the exception of the carriage/apron setup that is still a bit in the 'funky' mini lathe mindset. A single knob that pivots up/down/left/right would have been absolutely awesome in my book, but what we have is enough if I can get it to be a tool-less operation. I won't do a ton of off-size threading, so my intention is to mess with gear changes as little as possible. I will do a lot of boring, however, so the ability to set up at an internal shoulder, plunge a bit, then feed out to the right for a smooth surface without having to time anything is desirable. I'm sure traverse from the center outward is similarly useful, since our perspective is even less informative for tool position front/back (and good old lookin' is a good companion for dials and DROs as a sanity check)

. Nah, I was really hoping to essentially get a 12x36 with a short bed in the 1228, and for the most part that's true, with the exception of the carriage/apron setup that is still a bit in the 'funky' mini lathe mindset. A single knob that pivots up/down/left/right would have been absolutely awesome in my book, but what we have is enough if I can get it to be a tool-less operation. I won't do a ton of off-size threading, so my intention is to mess with gear changes as little as possible. I will do a lot of boring, however, so the ability to set up at an internal shoulder, plunge a bit, then feed out to the right for a smooth surface without having to time anything is desirable. I'm sure traverse from the center outward is similarly useful, since our perspective is even less informative for tool position front/back (and good old lookin' is a good companion for dials and DROs as a sanity check)

As far as being slower to return to the start of the cut, it's worth mentioning I have no cross slide handle, lol (for now; PM is helping me out, there)

It's not very loud at all, Franko, just not silent-running like the gears. Like I said, it's kind of unusual for that to be the case, that something is louder than the noisy clashing of gears.

Yeah, I know, but that's the size I learned on, and I am adverse to change

As far as being slower to return to the start of the cut, it's worth mentioning I have no cross slide handle, lol (for now; PM is helping me out, there)

It's not very loud at all, Franko, just not silent-running like the gears. Like I said, it's kind of unusual for that to be the case, that something is louder than the noisy clashing of gears.

- Joined

- Feb 24, 2015

- Messages

- 1,382

I'm working on the little stuff now.

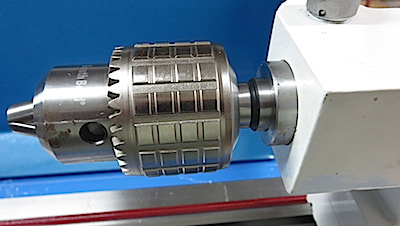

First, I had to cut 7/16" off the MT3 tapers for my live center and drill chuck to get full length on the quill travel.

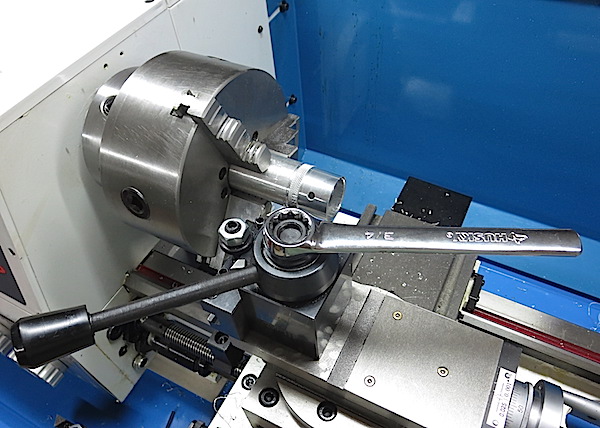

And, a custom wrench for my QCTP.

Now they don't eject until the quill is about an eighth past zero.

And, last but not least, riser block to stand on in front of the lathe. It is 3" tall by 16" wide.

Taller would be better, but it would interfere with the bottom drawers.

I put a handle on the side to make it easier to pick up and move.

At that width, I can sit on a stool to peruse my lower drawers.

My knees don't squat any more.

First, I had to cut 7/16" off the MT3 tapers for my live center and drill chuck to get full length on the quill travel.

And, a custom wrench for my QCTP.

Now they don't eject until the quill is about an eighth past zero.

And, last but not least, riser block to stand on in front of the lathe. It is 3" tall by 16" wide.

Taller would be better, but it would interfere with the bottom drawers.

I put a handle on the side to make it easier to pick up and move.

At that width, I can sit on a stool to peruse my lower drawers.

My knees don't squat any more.

Last edited:

- Joined

- May 14, 2015

- Messages

- 179

Nice! If it's got enough spring in it to have anti-fatigue properties, it'll definitely be easier to clean than a soft mat. Do my eyes deceive me, or are the two holes in the headstock behind your spindle open? Those two are what hold the main PC card down, and were not present on mine, either. I think they're like M6 or something, from the parts list.

"I asked Matt if the 1228 was a shorter version of the 1236. It isn't. The 1236 is a more robust lathe."

Oh, I could tell that from the weights; I was referring to feature set, which is very similar between the 1228 and typical 1236's (MT5 spindle, MT3 tailstock, D1-4 cam lock, ~2HP motor, power cross feed, separate lead/feed rods, selectable gears). A friend's 12x36 Chicom uses the same tapers, chucks, tailstock, horsepower (though 3-phase and higher amp draw), and apart from overall bulk differs only in having a selectable third change gear (ours is manual) and beefier BXA QCTP. Also some minor controls layout differences (selectable feed/thread direction knob). That feature set is what sold me on the lathe as a good starter/trainer piece.

TCB

"I asked Matt if the 1228 was a shorter version of the 1236. It isn't. The 1236 is a more robust lathe."

Oh, I could tell that from the weights; I was referring to feature set, which is very similar between the 1228 and typical 1236's (MT5 spindle, MT3 tailstock, D1-4 cam lock, ~2HP motor, power cross feed, separate lead/feed rods, selectable gears). A friend's 12x36 Chicom uses the same tapers, chucks, tailstock, horsepower (though 3-phase and higher amp draw), and apart from overall bulk differs only in having a selectable third change gear (ours is manual) and beefier BXA QCTP. Also some minor controls layout differences (selectable feed/thread direction knob). That feature set is what sold me on the lathe as a good starter/trainer piece.

TCB