-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm 1228-vf-lb Lathe Preparations

- Thread starter Franko

- Start date

- Joined

- Feb 24, 2015

- Messages

- 1,382

Last couple of days have required some shop rearrangement to accommodate the much larger lathe.

I removed the shop press to under the shed roof in front of the garage. I had made new heavier feet for so it could have wheels when I first got it, but never painted them. Thay needed to be removed and painted so they won't rust outside.

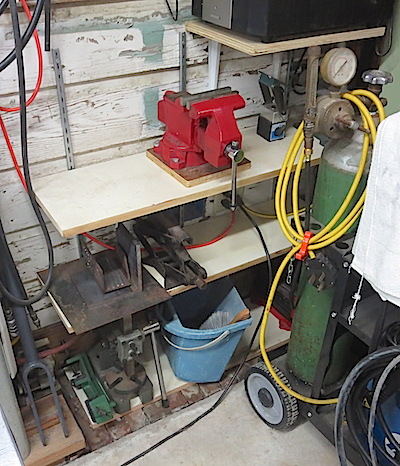

The small wooden bench needed to be lightened up and made more movable. I stored a 1-ton arbor press and some other heavies on it and on the under shelf. I put up a small shelf in the corner to hold the heavies.

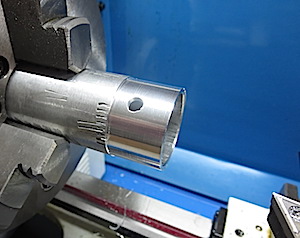

And, of course some chip making to see how slick it will cut on some scrap aluminum tube.

The cut looks 'baby-butt' smooth to me.

I removed the shop press to under the shed roof in front of the garage. I had made new heavier feet for so it could have wheels when I first got it, but never painted them. Thay needed to be removed and painted so they won't rust outside.

The small wooden bench needed to be lightened up and made more movable. I stored a 1-ton arbor press and some other heavies on it and on the under shelf. I put up a small shelf in the corner to hold the heavies.

And, of course some chip making to see how slick it will cut on some scrap aluminum tube.

The cut looks 'baby-butt' smooth to me.

Last edited:

- Joined

- May 14, 2015

- Messages

- 179

Let's just...assume, that I'm a moron that can't read directions; is there some special trick to engaging the power feed/traverse, or is it just super hitchy? My half-nuts engage well enough (very haltingly since they're tight) but the power lever, twisted toward either direction (talk about a funky control system) is solidly locked in every direction of motion. There's some play, but a very solid 'something' blocking additional motion toward engagement. My suspicion is it either takes a really long time for all the new gears to align (my gross-rate 3-position gear knob is like this, and appears to only function at a specific gear mesh point and is otherwise locked out) or the half-nut interlock that prevents feed/thread being both engaged is out of whack and the feed knob 'thinks' the nuts are always engaged. Oh well, made a few token chips just for funsies using the threading feed (I need to either get a real chuck key --mine is missing so I'm using a 3/8" ratchet-- or really lay into the thing, since a 1" diameter aluminum tube was spinning in the chuck WAY easier than I've ever seen before. Chuck was definitely tightening, so I'm wondering if the jaw finish is slippery or something)

I also completed my first 'mod' to the busted-up gearbox door that doesn't fit my setup well anyway. Some scrap hot-roll sheet of similar gage, a beefy piece of bar to beat the edges over, some quick dimensions & pop-rivets, and Bob's-your-uncle. Yeah right, it was way more tedious than that to get everything to line up (especially since the drip-line flange inside the lid had to be folded at the back for the lid to shut right) and to get those annoying hinge screws attached with the thing against the wall, but I think it's done, for now (paint & cleaning comes later, if ever). Fits real good, now, and I can still get the door about 1/2 way open to easily access the change gear and spindle (looks like enough thread for a spider at some point). More importantly, I can use the lathe, now (door safety switch made it kind of hard to check things out, hence the mod before function check). FYI, there is nothing retaining the door hinge pins; they ends are peened, but they are two pins inserted at each end that are disguised to look like a properly retained pin; replacement is advised.

One other thing I discovered whilst wrestling with the door; this stand is laughably flexible. I'm kinda ****** since it cost about 400$ with shipping, and I can rock the thing front-to-back a good 1/2" or so with little effort at the natural frequency. I had a feeling that linear bolt patter was going to be an issue, so now it looks like I'll be sourcing some 1/2" thick plate to make wide footing with, then figuring out how to bolt through the stand with some proper shanked fasteners. Hell, I may be sourcing 100$ worth of angle iron and hiring a buddy to just replace the damn thing.

I finished my inventory, and the only 'important' missing stuff was the cross slide handle, spare V belt, one of the external 3 jaw jaws, and the chuck key. Many small odds and ends that I have equivalents of already, and even more random fasteners were either omitted or worked loose (the screws holding the primary electrical board down were never installed, and the backsplash had only one fastener left at delivery). Trying really hard not to see this thing as a sow's ear, and if I can get the power feed to work, I'll know for sure.

I have a couple other quick mods planned; bought a cheap but much nicer RPM gage/display that looks like it should fit the window in the 1228, and a volt/ammeter & display to go somewhere else as cheap fuse insurance (my garage has no access to the building's breaker panel) just in case. Got a like-new '46 Skinner " 4-jaw, and a fresh backplate is on its way for fitting. Test/dial indicators should be here this week so I can get the 'real' checkout done.

TCB

I also completed my first 'mod' to the busted-up gearbox door that doesn't fit my setup well anyway. Some scrap hot-roll sheet of similar gage, a beefy piece of bar to beat the edges over, some quick dimensions & pop-rivets, and Bob's-your-uncle. Yeah right, it was way more tedious than that to get everything to line up (especially since the drip-line flange inside the lid had to be folded at the back for the lid to shut right) and to get those annoying hinge screws attached with the thing against the wall, but I think it's done, for now (paint & cleaning comes later, if ever). Fits real good, now, and I can still get the door about 1/2 way open to easily access the change gear and spindle (looks like enough thread for a spider at some point). More importantly, I can use the lathe, now (door safety switch made it kind of hard to check things out, hence the mod before function check). FYI, there is nothing retaining the door hinge pins; they ends are peened, but they are two pins inserted at each end that are disguised to look like a properly retained pin; replacement is advised.

One other thing I discovered whilst wrestling with the door; this stand is laughably flexible. I'm kinda ****** since it cost about 400$ with shipping, and I can rock the thing front-to-back a good 1/2" or so with little effort at the natural frequency. I had a feeling that linear bolt patter was going to be an issue, so now it looks like I'll be sourcing some 1/2" thick plate to make wide footing with, then figuring out how to bolt through the stand with some proper shanked fasteners. Hell, I may be sourcing 100$ worth of angle iron and hiring a buddy to just replace the damn thing.

I finished my inventory, and the only 'important' missing stuff was the cross slide handle, spare V belt, one of the external 3 jaw jaws, and the chuck key. Many small odds and ends that I have equivalents of already, and even more random fasteners were either omitted or worked loose (the screws holding the primary electrical board down were never installed, and the backsplash had only one fastener left at delivery). Trying really hard not to see this thing as a sow's ear, and if I can get the power feed to work, I'll know for sure.

I have a couple other quick mods planned; bought a cheap but much nicer RPM gage/display that looks like it should fit the window in the 1228, and a volt/ammeter & display to go somewhere else as cheap fuse insurance (my garage has no access to the building's breaker panel) just in case. Got a like-new '46 Skinner " 4-jaw, and a fresh backplate is on its way for fitting. Test/dial indicators should be here this week so I can get the 'real' checkout done.

TCB

- Joined

- Feb 24, 2015

- Messages

- 1,382

TCB, you aren't a moron. The manual does not cover how to operate the longitudinal and cross feed lever.

On the top of the lever are arrows. Front and back for cross feed, and left and right for longitudinal feed.

Turn the handle 180º to select which direction you want to feed.

To engage the feed, pull the handle towards you and move it up for longitudinal or down for cross feed.

It will only move in the direction of the feed selected indicated on the lever.

You may have to jiggle the change gear knobs to engage the feed gears.

If the threading screw and hex rod aren't turning, they aren't engaged.

The chart on the top describes what settings are required for different feed rates.

I had no problem with the linear bolt pattern. Your issue is with the stand. The stand I made is rock solid. For additional support, I got a couple 1/4" cold roll plates about an inch larger than the footprint of the feet and put them between the pan and the feet. (8" x 7" and 8" x 12")

If you purchase cold roll, be sure it is sawed and not sheared. Shearing warps it.

For your issue, a couple of plates the size of the stands would surely stiffen it up.

Probably a couple pieces of 3/4" plywood would work.

I don't know how thin the top is, but I'd bet that is the source of the flexing. Use 1/2" bolts are recommended in the manual.

I don't think it supposed to come with an extra belt. It is a regular v-belt and I don't see it wearing out for a long time.

Sorry to hear about the other missing parts.

On the top of the lever are arrows. Front and back for cross feed, and left and right for longitudinal feed.

Turn the handle 180º to select which direction you want to feed.

To engage the feed, pull the handle towards you and move it up for longitudinal or down for cross feed.

It will only move in the direction of the feed selected indicated on the lever.

You may have to jiggle the change gear knobs to engage the feed gears.

If the threading screw and hex rod aren't turning, they aren't engaged.

The chart on the top describes what settings are required for different feed rates.

I had no problem with the linear bolt pattern. Your issue is with the stand. The stand I made is rock solid. For additional support, I got a couple 1/4" cold roll plates about an inch larger than the footprint of the feet and put them between the pan and the feet. (8" x 7" and 8" x 12")

If you purchase cold roll, be sure it is sawed and not sheared. Shearing warps it.

For your issue, a couple of plates the size of the stands would surely stiffen it up.

Probably a couple pieces of 3/4" plywood would work.

I don't know how thin the top is, but I'd bet that is the source of the flexing. Use 1/2" bolts are recommended in the manual.

I don't think it supposed to come with an extra belt. It is a regular v-belt and I don't see it wearing out for a long time.

Sorry to hear about the other missing parts.

Last edited:

- Joined

- May 14, 2015

- Messages

- 179

"To engage the feed, pull the handle towards you and move it up for longitudinal or down for cross feed."

Figures. The one degree of freedom I didn't yank the knob along. Still bugs me that the lever moves identically for both feed directions --seems less than safe, kind of like having the E-stop on the far side of the chuck. Whatevs, we'll try again in the morning before work. Thanks for the info, that was gonna drive me nuts all night.

I thought about just procuring an old tooling or gaging plate somewhere and having it torched in half for the feet. I think you're right that if I can just beam the load out to the vertical webs of the bases, all will be well. Cold roll is probably more available and easier to drill, though, and plenty stiff enough. The table top was like 1/8" thick or less and with no stiffeners, as I recall, so I'm not super surprised a 5" wide base wobbles a bit. Probably gonna bolt a piece of beefy channel iron up inside the supports opposite the feet, too. I haven't attached the lower/center panel yet since I need access under the machine, but I doubt it would stiffen things significantly in that direction.

TCB

Figures. The one degree of freedom I didn't yank the knob along. Still bugs me that the lever moves identically for both feed directions --seems less than safe, kind of like having the E-stop on the far side of the chuck. Whatevs, we'll try again in the morning before work. Thanks for the info, that was gonna drive me nuts all night.

I thought about just procuring an old tooling or gaging plate somewhere and having it torched in half for the feet. I think you're right that if I can just beam the load out to the vertical webs of the bases, all will be well. Cold roll is probably more available and easier to drill, though, and plenty stiff enough. The table top was like 1/8" thick or less and with no stiffeners, as I recall, so I'm not super surprised a 5" wide base wobbles a bit. Probably gonna bolt a piece of beefy channel iron up inside the supports opposite the feet, too. I haven't attached the lower/center panel yet since I need access under the machine, but I doubt it would stiffen things significantly in that direction.

TCB

- Joined

- Mar 1, 2015

- Messages

- 17

The parts list suggest an extra belt, but the manual also indicates the lathe ships without the belt installed,

so I think one belt is it.

The feed level had me stumped as well, and the manual did not help. The operation makes perfect sense

once I figured it out.

The stand is not very impressive for the price, but I have not found it to be too floppy. Better bracing between

the legs might go a longs ways towards stiffening it up.

so I think one belt is it.

The feed level had me stumped as well, and the manual did not help. The operation makes perfect sense

once I figured it out.

The stand is not very impressive for the price, but I have not found it to be too floppy. Better bracing between

the legs might go a longs ways towards stiffening it up.

- Joined

- Aug 12, 2013

- Messages

- 858

Also, sometimes you have to slightly move the carriage travel handwheel to engage longitudinal feed if the gears aren't meshing (or cross slide handwheel to engage cross feed).

Flimsy sheet metal stands are a curse of lathes until you hit a certain price range.

Flimsy sheet metal stands are a curse of lathes until you hit a certain price range.

- Joined

- Feb 24, 2015

- Messages

- 1,382

The manual does mention rotating the feed handle, but does not mention that you have to pull it out to engage it.

Chuck the welder was with me and we managed to figure it out. He discovered pulling the handle and I discovered jiggling the change gear knobs.

I was concerned about accidentally engaging the y or x feed by pulling up or down, but I think they way it is implemented is fairly idiot proof — even though I've been known to excel at idiocy on occasion. You have to make a change by rotating the handle before you can switch between x and y feed. Also, by having to pull on it, it isn't going to be accidentally engaged if drop something on it or bump into it.

So, all in all, it seems as safe as it can be.

Chuck the welder was with me and we managed to figure it out. He discovered pulling the handle and I discovered jiggling the change gear knobs.

I was concerned about accidentally engaging the y or x feed by pulling up or down, but I think they way it is implemented is fairly idiot proof — even though I've been known to excel at idiocy on occasion. You have to make a change by rotating the handle before you can switch between x and y feed. Also, by having to pull on it, it isn't going to be accidentally engaged if drop something on it or bump into it.

So, all in all, it seems as safe as it can be.

- Joined

- May 14, 2015

- Messages

- 179

I'll just have to get used to looking down, more. Anyway, the power feed works (thanks) but only in two directions so far (right and away) so there is more work to be done. It briefly fed to the right, but I can't replicate it. Super hitchy, grindy action that requires a bit of force the first few times. Not sure how it 'checked out' for function before it shipped, unless I'm missing something. Feed rod wasn't damaged, btw, thought the lead screw is slightly bowed (.02 --not worried)