I was greatly inspired by Hackmasters beautiful oil can clone. I decided to do a run of my own with a simpler design. It was suggested that I start a new thread here and not hijack the other thread.

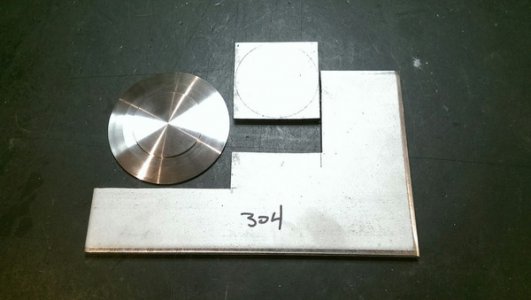

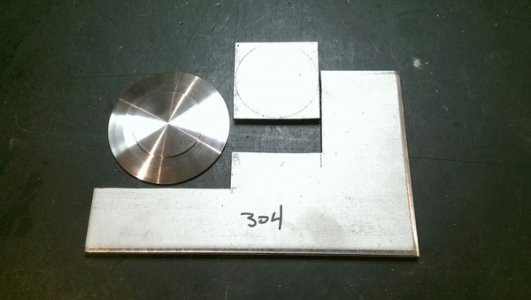

The plan was originally solid brass. I realized that the pump housing would add too much weight so I went with an aluminum pump housing.

I was sort of emulating this original as posted by Hackmaster:

Here is the base pattern:

Its about 3/16" thick at the edge. I will turn it down more when it is brass.

R

The plan was originally solid brass. I realized that the pump housing would add too much weight so I went with an aluminum pump housing.

I was sort of emulating this original as posted by Hackmaster:

Here is the base pattern:

Its about 3/16" thick at the edge. I will turn it down more when it is brass.

R

Attachments

Last edited: