@ 8am. Didn't do much better with the run outs. I tried to do a little test cutting and the results were really bad. Think most of my problems are wrong tooling and and dull tool bits. I've never been good at sharpening my tooling. Gonna buy a green wheel and "edjumacate myself more gooder sharpening techniques." L

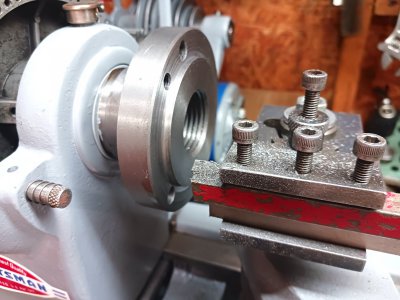

L My new QCTP tool holders have still not arrived. Now I'm just making excuses for my lack of skill.

My test cuts were "raspy" looking and I noticed if I just left the cutter in one spot it would continue to keep cutting very slightly inward without moving the compound slide handle. I'lI recheck all the gib screws and maybe add a "thumb" screw on the center to take up any detectable cross slide play. (This should not be necessary). I have about .010" cross slide nut play.

UPDATE: @8:45AM: I just noticed I had forgot to adjust the rear saddle gibs! They had not been adjusted at all when I assembled the lathe.