-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New restoration project! 12" Craftsman lathe.

- Thread starter LX Kid

- Start date

- Joined

- May 26, 2015

- Messages

- 875

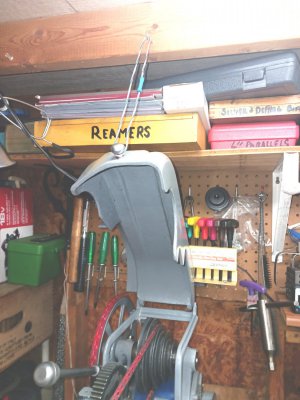

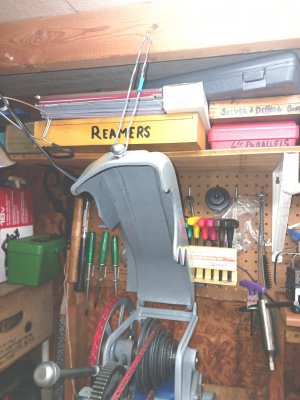

I love comments as it shows "someone" is following my thread even if it's "only" a moderator! LoL I'd like to trade my 8" 4-jaw for a 6" 4-jaw chuck or a 6" 3-jaw self centering Had some motor bounce so I shortened the drive belt and is smooth as silk now. I invented a hi-tech gear cover hold open device. I'll take a pic when I get a chance.Oh, I believe you, and I probably shouldn't have commented.. But I was just surprised that it had the heavy-duty 4-jaw included.

To help reduce change gear noise I'm going to spray the gears with with motorcycle chain lube. I did this on a South bend and it helped a lot. Noting to do now until my chuck back plate and QCTP get here. Anxious to turn a bunch of good metal into more worthless chips.

Attachments

Last edited by a moderator:

- Joined

- May 26, 2015

- Messages

- 875

HELP! Can't figure out why my smaller diameter motor, than what came with lathe, doesn't fit properly. The high speed sheave, far left, is so close to the motor it won't let me put the belt on it. Clearance is only about 1/8". To make it work I had to cut out the ends of the motor mount bracket and use large washers to hold it in place. (See pic). I could make two longer motor braces, or install a turn buckle, to allow motor to drop another 1/2", but why doesn't it fit?????

5/16/24: Just noticed, from pic #2, that my motor alignment is off about 1/4". Guess I'll take care of that this morning.

5/16/24: Just noticed, from pic #2, that my motor alignment is off about 1/4". Guess I'll take care of that this morning.

Attachments

Last edited:

- Joined

- May 26, 2015

- Messages

- 875

Did a couple of mods this morning to enhance use. In my junk pile I found this old QCTP and modded the mount so it would fit into my tool post mount. I would think it will give a little more rigidity for certain jobs. I also made a tool tray that's held in place between the ways and covered it with genuine naugahyde.. That will make for easy cleaning. Just gotta add trin around edges to keep little screws and parts from rolling off.

Attachments

- Joined

- May 26, 2015

- Messages

- 875

I fingered it out. It was too obvious but those things happen now and again! The adjustable belt from motor to the countershaft was two links too short. Added two links and all is good!HELP! Can't figure out why my smaller diameter motor, than what came with lathe, doesn't fit properly. The high speed sheave, far left, is so close to the motor it won't let me put the belt on it. Clearance is only about 1/8". To make it work I had to cut out the ends of the motor mount bracket and use large washers to hold it in place. (See pic). I could make two longer motor braces, or install a turn buckle, to allow motor to drop another 1/2", but why doesn't it fit?????

- Joined

- May 26, 2015

- Messages

- 875

What else can I do or make while I wait for my chuck back plate to arrive? Kind of anxious to do a first cut. I already did a tailstock alignment and may have to insert a .001-.002" shim to bring alignment up just a hair. Need to go to Wal-Mart and buy some motorcycle chain lube spray for the change gears. I did that on a South Bend and it quieted gear noise done nicely with proper gear meshing. It sticks and doesn't fling off. Might try it on the back gears as well.

UPDATE: 05/17/24. I rechecked my change gear adjustments and discovered one of the gears had loosened up after being run awhile. This lathe has not been run in years until now. After readjusting the noise was reduced significantly. After running another day or two I'll recheck all the gear mesh again.

UPDATE: 05/17/24. I rechecked my change gear adjustments and discovered one of the gears had loosened up after being run awhile. This lathe has not been run in years until now. After readjusting the noise was reduced significantly. After running another day or two I'll recheck all the gear mesh again.

Last edited:

- Joined

- May 26, 2015

- Messages

- 875

I kept hearing a tick tick tick from the countershaft area and noticed that my large sheave screw for countershaft keeps loosening up. There is a "slight" wobble of the sheave which doesn't help things. Did an inspection of the countershaft and found the detent for securing the sheave was very shallow. Drilled the detent a little deeper and used thread lock on the 5/16 x 20 securing screw. Hope this does it.

Last edited:

- Joined

- May 26, 2015

- Messages

- 875

If Anyone is interested, the final restoration cost was $1275.00. I still need a 6" 3-jaw chuck though. The biggest cost was downsizing the 54" bed to a 42" bed. Now I need to sell the 54" bed that I don't need cause it was too long to fit in my shop.

- Joined

- May 26, 2015

- Messages

- 875

"JUST WHEN YOU THINK ALL IS GOOD, BAMM YOU GET KNOCKED DOWN IN THE DIRT!"

I engaged the the half nuts and everything came to a screeching halt! I looked do down at the far end of the lead screw and the support was broken and the lead screw in a bad position! Glad I had a spare support.

I dropped the apron trying to figure out what locked up. It was the mitre gear. Evidently there was supposed to be shims behind for mesh alignment but none were there when I took it apart so I did not know. I installed .015" shims and all is "once again" good! I'll bet that is what happened to the former owner and why it sat for so many years. In an earlier post I had mentioned I had to replace the mitre gear assembly.

I engaged the the half nuts and everything came to a screeching halt! I looked do down at the far end of the lead screw and the support was broken and the lead screw in a bad position! Glad I had a spare support.

I dropped the apron trying to figure out what locked up. It was the mitre gear. Evidently there was supposed to be shims behind for mesh alignment but none were there when I took it apart so I did not know. I installed .015" shims and all is "once again" good! I'll bet that is what happened to the former owner and why it sat for so many years. In an earlier post I had mentioned I had to replace the mitre gear assembly.