- Joined

- Nov 7, 2018

- Messages

- 186

Since I wasn't impressed with the DROpros display mount and arm, I made my own. The arm is .625" x 1.5" aluminum bar stock and the mounting bracket was made from a scrap chunk of 1.5" aluminum, cut and finished to 4" base x 5" tall. I wanted to have the ability to swing the entire display out of the way to remove the headstock top cover. I also wanted it at a comfortable working hight. The base is drilled and tapped for two 5/16-18 mounted atop the electrical cabinet. A piece of 1/4" x 3" flat strap (same hole layout) was used as backer to prevent the cabinet from flexing. Two bolts secures everything from the inside if the cabinet.

I like the working hight. The speed control is the left knob while the smaller knob on the right switches between SFM or RPM.

The DROPRO's bracket/arm had the display rotated to the right about 1/3 bubble off on a 8" level driving me nuts.

This looks much better .

.

Here you can see the swing clearing the way to remove the top cover on the headstock.

The backer plate really prevents any flexing. The cantilever weight is enough to flex the 16 ga, enclosure and would more than likely bounce/vibrate with the machine running. The whole assembly is very solid.

The head also rotates right to left. This is the extreme rotation to the left keeping slight slack on the cables.

The power cable will straighten up some when rotated to the far right while the two armored cables will slacken.

The rest of the cables will be secured after the backsplash is reinstalled.

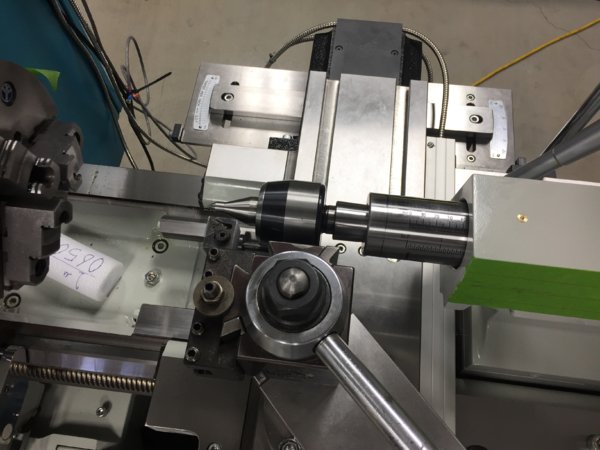

The tool post T-nut was removed and drilled out for a 3/4-16 tap. The Aloris uses a larger stud than what the machine came with.

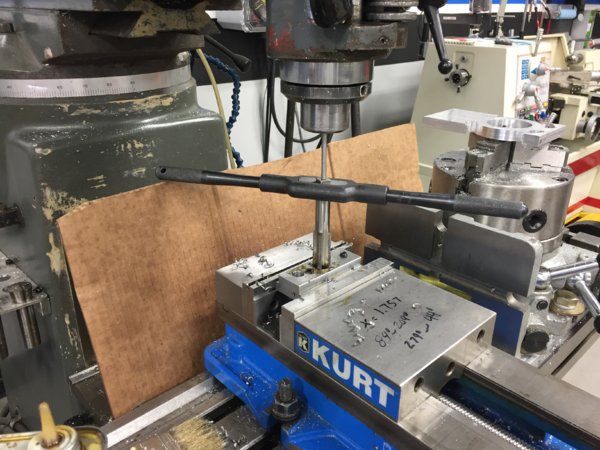

The benefit of a long table, two projects at once. A push of a button and the machine will be back on center over the rotary table project.

The CXA really fits nice. I wanted to get more measurements for the tailstock DRO quill bracket with the QCTP in place. Plenty of room even with a short live center.

Looks right at home.

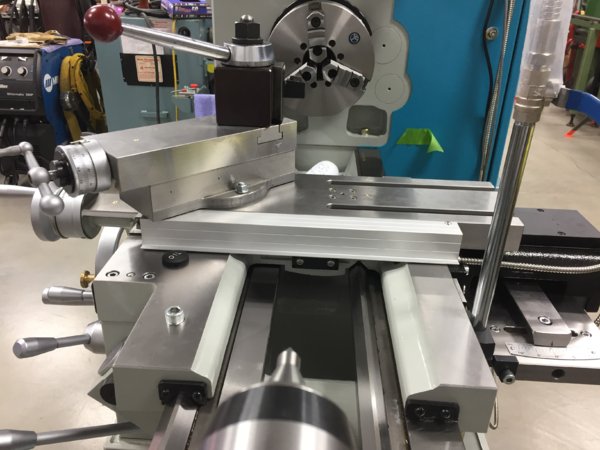

Next punch list item was to indicate in the taper attachment. I got it within .0005" in 12.5" I need to drill two holes and pin in place ensuring it stays located. Any movement will result in cross feed leads screw binding. The deadman clamp and lineage rod also were installed for indicating.

The taper was set as far as possible, the carriage traveled smoothly by hand. A pice of tape was marked prior and after travel and matched up with the DRO readings. The 1440's taper attachment works well too but, it required the cross slide nut to be removed and the deadman clamp. The ACRA only requires the deadman clamp and is much smother.

Another view. The clearance between the Y scale/cover and the deadman clamp worked out well.

I'm hoping to make real progress on the TS scale tomorrow, then pin the tapper attachment and get the back splash back on.

I see chips in the near future.

Thanks for stopping by.

Paco

I like the working hight. The speed control is the left knob while the smaller knob on the right switches between SFM or RPM.

The DROPRO's bracket/arm had the display rotated to the right about 1/3 bubble off on a 8" level driving me nuts.

This looks much better

Here you can see the swing clearing the way to remove the top cover on the headstock.

The backer plate really prevents any flexing. The cantilever weight is enough to flex the 16 ga, enclosure and would more than likely bounce/vibrate with the machine running. The whole assembly is very solid.

The head also rotates right to left. This is the extreme rotation to the left keeping slight slack on the cables.

The power cable will straighten up some when rotated to the far right while the two armored cables will slacken.

The rest of the cables will be secured after the backsplash is reinstalled.

The tool post T-nut was removed and drilled out for a 3/4-16 tap. The Aloris uses a larger stud than what the machine came with.

The benefit of a long table, two projects at once. A push of a button and the machine will be back on center over the rotary table project.

The CXA really fits nice. I wanted to get more measurements for the tailstock DRO quill bracket with the QCTP in place. Plenty of room even with a short live center.

Looks right at home.

Next punch list item was to indicate in the taper attachment. I got it within .0005" in 12.5" I need to drill two holes and pin in place ensuring it stays located. Any movement will result in cross feed leads screw binding. The deadman clamp and lineage rod also were installed for indicating.

The taper was set as far as possible, the carriage traveled smoothly by hand. A pice of tape was marked prior and after travel and matched up with the DRO readings. The 1440's taper attachment works well too but, it required the cross slide nut to be removed and the deadman clamp. The ACRA only requires the deadman clamp and is much smother.

Another view. The clearance between the Y scale/cover and the deadman clamp worked out well.

I'm hoping to make real progress on the TS scale tomorrow, then pin the tapper attachment and get the back splash back on.

I see chips in the near future.

Thanks for stopping by.

Paco

Last edited by a moderator: