I have a PDF model which does not have a depth stop. Well I did mention in the past the power down feed depth limit can be used as depth stop but it's not designed to be used that way & since I know what components look like that allows it to work that way I didn't want to cause wear or damage from using it that way often. It doesn't repeat as well as I want anyway. Been wanting a strong solid depth stop so I finally made one.

Here's what I came up with & it works just as I hoped it would. I'm

very happy with it.

I used a Morton quick release quill stop that's made for BPs. Which means I used the same 1/2"-20 thread like on BPs. Here is showing the quill stop in action.

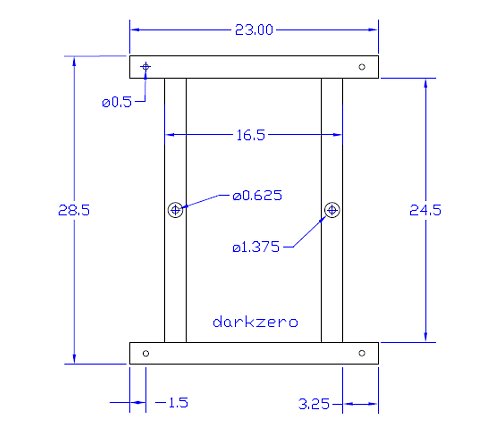

Here you can see how it's mounted. I probably went overboard on the thickness of everything but I want it to repeat well with no flex & is also why I decided not to use aluminum. And it does repeat excellent!

Quill fully extended.

I haven't decided if I will paint all these parts when I repaint the quill bracket. I kind of like it bare, maybe I'll just give them a final finish by hand. No rust issues here in Socal anyway.

The rest of the pics are just some WIP pics. I didn't take pics of every op & I won't post everything but you'll get the idea.

Machined the quill bracket on the lathe to ensure the top surface would be fairly square to quill.

Might as well do the bottom too.

Cleaning up the quill bracket.

Verified how square it is, measuring to the table. I'm happy with that.

Working on the stop bracket.

The head casting is not perfectly square as I needed it to be because of all the filler. It was about 1° off so to compensate for that I milled the angle using an adj angle block.

Working on the rod holder that mounts to the quill bracket.

This is how my quill DRO used to mount. I kept that method the same but I went with a bigger bolt for for mounting the depth stop as you can see above, M6 to M8.

Also made a new mount & is why I cleaned up the cavity on the quill bracket, old vs new.

Thanks for looking!