-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Monarch 60

- Thread starter Beckerkumm

- Start date

- Joined

- Apr 10, 2021

- Messages

- 625

A little more work on Monarch. Cleaned and painted the chip bin. That kind of work is good preparation for the chain gang.

Since I'm making gears for Metric threading, I did some work on the lead screw reverse. The Monarch toolroom lathes had had the LSR on the apron and it was a good deal. Their engine lathes had a lever on the headstock. There is a spring loaded ball inside the casting so you push the end in and then move the lever up or down until it hits a detent on the headstock. Works but not very handy. I didn't want to muck up the original so drilled and tapped a 5/16 hole and added an extension. While you can reverse the screw at lower rpm, I intend to use the clutch to stop the spindle when threading, hit the lever and reverse the feed and leave the half nut engaged. The clutch stops very quickly so it will work.

My vfd set up would also allow me to accomplish the same thing using the forward and reverse buttons but the location isn't very handy. That system is what I use on the CVA and Smart Brown 1024, both designed by Mark Jacobs and using a proximity stop. Dave

Since I'm making gears for Metric threading, I did some work on the lead screw reverse. The Monarch toolroom lathes had had the LSR on the apron and it was a good deal. Their engine lathes had a lever on the headstock. There is a spring loaded ball inside the casting so you push the end in and then move the lever up or down until it hits a detent on the headstock. Works but not very handy. I didn't want to muck up the original so drilled and tapped a 5/16 hole and added an extension. While you can reverse the screw at lower rpm, I intend to use the clutch to stop the spindle when threading, hit the lever and reverse the feed and leave the half nut engaged. The clutch stops very quickly so it will work.

My vfd set up would also allow me to accomplish the same thing using the forward and reverse buttons but the location isn't very handy. That system is what I use on the CVA and Smart Brown 1024, both designed by Mark Jacobs and using a proximity stop. Dave

Attachments

- Joined

- Feb 25, 2021

- Messages

- 3,273

My CK has the apron mounted leadscrew reverse, but I don't change directions without disengaging the clutch first either. Just not inclined to be that hard on the gearbox and dogs on those selectors. Haven't tried setting up the stops on the reversing rod.Since I'm making gears for Metric threading, I did some work on the lead screw reverse. The Monarch toolroom lathes had had the LSR on the apron and it was a good deal. Their engine lathes had a lever on the headstock. There is a spring loaded ball inside the casting so you push the end in and then move the lever up or down until it hits a detent on the headstock. Works but not very handy. I didn't want to muck up the original so drilled and tapped a 5/16 hole and added an extension. While you can reverse the screw at lower rpm, I intend to use the clutch to stop the spindle when threading, hit the lever and reverse the feed and leave the half nut engaged. The clutch stops very quickly so it will work.

What I do find really handy when threading is the three-turn stop on the carriage. Use the compound to increment depth for the cut, and easily back out and return to the same thread depth just by turning the cross slide off the stop and back to it. But there are a lot of different techniques and I guess it all comes down to what works for you.

One question, I'm not sure that metric threading will work if you loose alignment on the gears/dogs going between F-N-R on the leadscrew direction. Let me know how that works out. I think many folks leave the leadscrew direction selector the same, and just reverse the spindle to back up the carriage when doing metric.

Last edited:

- Joined

- Apr 10, 2021

- Messages

- 625

Interesting thought about whether the LSR will lose the reference even if the half is left engaged. Success is fleeting, failure is forever.

I agree that the two turn stop on the cross slide dial is very nice. I just feed in from the cross slide on the 1024 but both the 60 and the CVA have the stop for feeding from the compound.

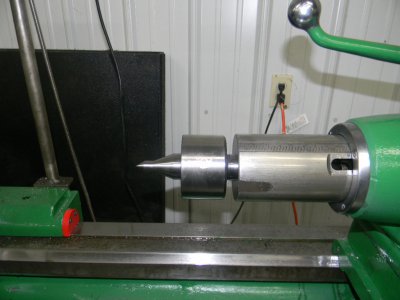

Also found a good deal on a Riten extended tip live center. I got a Riten and Skoda standard tip with the machine that are in good shape but like the longer tip.

Dave

I agree that the two turn stop on the cross slide dial is very nice. I just feed in from the cross slide on the 1024 but both the 60 and the CVA have the stop for feeding from the compound.

Also found a good deal on a Riten extended tip live center. I got a Riten and Skoda standard tip with the machine that are in good shape but like the longer tip.

Dave

Attachments

- Joined

- Jun 12, 2014

- Messages

- 5,128

Similar to Dave, I almost always use my CNC/extended point live centers, the standard point I use for heavy stock. I also have one of the Skoda live center its with interchangeable tips which comes in handy for certain types of stock where you do not want to center drill.

I would also concur with Rabler that even with the ability to cut metric threads, you would need to leave the half-nut engaged while threading metric with an imperial lead screw. Threading dial would be specific to TPI and not metric threads.

I would also concur with Rabler that even with the ability to cut metric threads, you would need to leave the half-nut engaged while threading metric with an imperial lead screw. Threading dial would be specific to TPI and not metric threads.

- Joined

- Apr 10, 2021

- Messages

- 625

The half nut will need to stay engaged, the issue is whether the lead screw reverse, even with the half nut clamped down, will maintain the reference to not muck up the threads. I will report back when I get the 127T gear and compound it with the 75T on the lathe. I'm hopeful that waiting until the clutch has stopped the lead screw and then engaging the LSR will allow the experiment to work. Dave

- Joined

- Apr 10, 2021

- Messages

- 625

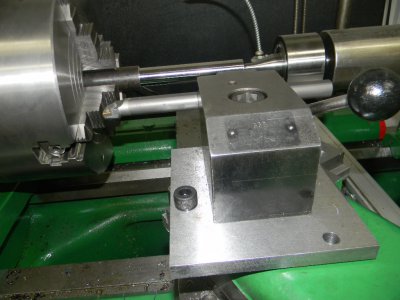

Made a few adjustments to Monarch. It came with a million KDK holders so I'm using it even though I'm a Multifix guy. Not a bad system but has a couple of flaws. There isn't much surface area for use on the monarch compound and the post had a tendency to move under heavy load unless really tightened down hard. The post also needs to be turned for boring so some way to register it fairly close was needed.

I made a new T nut and surface ground it flat with the compound. Put a new base plate on the post and enlarged it so I could put a screw into the T nut to register it in both directions. I drilled a 27/64" hole and turned a socket head bolt down to match and then rethreaded to 3/8 so the fit was pretty tight. The post is only repeatable to a few thou but it gets me in the ball park and i really only need higher precision when parting. We will see how it works but the post no longer wants to move even with the 10 hp motor loading up.

Dave

I made a new T nut and surface ground it flat with the compound. Put a new base plate on the post and enlarged it so I could put a screw into the T nut to register it in both directions. I drilled a 27/64" hole and turned a socket head bolt down to match and then rethreaded to 3/8 so the fit was pretty tight. The post is only repeatable to a few thou but it gets me in the ball park and i really only need higher precision when parting. We will see how it works but the post no longer wants to move even with the 10 hp motor loading up.

Dave

Attachments

- Joined

- Apr 10, 2021

- Messages

- 625

Not much happening on the Monarch lately. Although I have a million KDK tool holders I missed the Multifix so I've been sourcing used holders and even found a new old stock tool post that is a Euro clone, I'm guessing from the 1970's. I have several examples of multifix on other lathes, including an original Minder and a never used Enco from the 1970's when they imported good stuff. I wanted a size B for the Monarch as I use primarily 1" or smaller tooling. I also bought a set and some holders from Pewe which are Chinese copies but pretty decent quality. I have many version of tool holder copies from Switzerland, Germany, and who knows where and the fits can be slightly different. The Pewe post fits the original Minder and clones licensed by Minder but some of the later ones can be tight. In this case, the Pewe had trouble with some of my Euro holders while the NOS post i found fit everything. My guess is the tooth configuration is slightly different as measurements showed no more than .0002 variation in the body of the post. I didn't check the contact but turning a .25" DOC didn't cause problems and i seldom get more greedy than that.

I made a new T nut and locked it down with set screws, made a spacer to lift the post about .25" and fit it into the slot on the compound. The nut and flat on the stud were made to fit the 1-1/16 wrench for the tailstock and the threads were 3/4" UNC on the bottom and UNF on the top- mainly because i bought the wrong flange nut. I'll make a new one at some point but for now I just milled the hex down to fit the wrench. Looks like I forgot to take a picture of everything installed but that will follow. Dave

I made a new T nut and locked it down with set screws, made a spacer to lift the post about .25" and fit it into the slot on the compound. The nut and flat on the stud were made to fit the 1-1/16 wrench for the tailstock and the threads were 3/4" UNC on the bottom and UNF on the top- mainly because i bought the wrong flange nut. I'll make a new one at some point but for now I just milled the hex down to fit the wrench. Looks like I forgot to take a picture of everything installed but that will follow. Dave

Attachments

- Joined

- Apr 10, 2021

- Messages

- 625

Here is a picture of the Multifix.

The next project to to finish the change gears for metric threading. I ordered a 127T gear from Linn. The price was $130 which is cheaper than me wrecking several cutting gears as I'm a mediocre machinist. I found a great guy who was scrapping a monarch 60 and got a bunch of clutch and gear parts. That allows me to use the Monarch to modify the Monarch.

I had shown modifying the small gears before but now am compounding the 127T to the 75T spur gear. The DP of the new gear is 16 vs 12 for the old so the 127 is slightly larger but there appears to be enough adjustment on the banjo to handle it.

My boring bars are still mounted for KDK so I used it to bore out the gear to slip over the 75T. Using the Monarch for drilling is much nicer than the MT2 tailstock on the Smart Brown. I considered a press fit but I'm not sure I can access the banjo bolts with the larger gear in place so I left about .001 clearance and can remove the 127 gear without disturbing the original 75.

Next will be attaching the two and adjusting the distance between them with washers so the new gear meshes with the smaller one. I skimmed the hub to make sure it is running true to the bore, and put new bearings in it ( SKF Explorer ) . When I get it done, I expect i will find that I should have done it differently. If it matters I still have the original gear and even a second 127T but hoping for once to not need to redo.

Dave

The next project to to finish the change gears for metric threading. I ordered a 127T gear from Linn. The price was $130 which is cheaper than me wrecking several cutting gears as I'm a mediocre machinist. I found a great guy who was scrapping a monarch 60 and got a bunch of clutch and gear parts. That allows me to use the Monarch to modify the Monarch.

I had shown modifying the small gears before but now am compounding the 127T to the 75T spur gear. The DP of the new gear is 16 vs 12 for the old so the 127 is slightly larger but there appears to be enough adjustment on the banjo to handle it.

My boring bars are still mounted for KDK so I used it to bore out the gear to slip over the 75T. Using the Monarch for drilling is much nicer than the MT2 tailstock on the Smart Brown. I considered a press fit but I'm not sure I can access the banjo bolts with the larger gear in place so I left about .001 clearance and can remove the 127 gear without disturbing the original 75.

Next will be attaching the two and adjusting the distance between them with washers so the new gear meshes with the smaller one. I skimmed the hub to make sure it is running true to the bore, and put new bearings in it ( SKF Explorer ) . When I get it done, I expect i will find that I should have done it differently. If it matters I still have the original gear and even a second 127T but hoping for once to not need to redo.

Dave

Last edited:

Similar threads

- Replies

- 0

- Views

- 76

- Replies

- 26

- Views

- 2K

- Replies

- 6

- Views

- 780

- Replies

- 25

- Views

- 2K