- Joined

- Jul 5, 2014

- Messages

- 2,849

Well the 4th set of lines just arrived. Later than they said. For some reason they shipped a set, then requested they be returned. Then sent them out again. I suspect the first shipment wasn't checked for equal line length and called them back. The set I got was opened and taped back up.

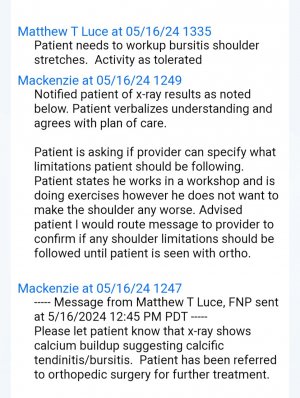

So now I'm waiting for my shoulder to get better. I woke up about two weeks ago and my left shoulder hurt like he'll. Pretty much couldn't move my arm. It's somewhat better now, I was able to use the power draw bar on my mill this morning with a lot of pain, but I got the customer part finished.

Hopefully soon I'll heal up and get this little project finished. It's hell getting old

So now I'm waiting for my shoulder to get better. I woke up about two weeks ago and my left shoulder hurt like he'll. Pretty much couldn't move my arm. It's somewhat better now, I was able to use the power draw bar on my mill this morning with a lot of pain, but I got the customer part finished.

Hopefully soon I'll heal up and get this little project finished. It's hell getting old

Last edited: