- Joined

- Feb 24, 2015

- Messages

- 1,382

Thanks, Darrell. I got the TIG to weld aluminum as that is what I work with mostly. Everyone said don't try aluminum until you are proficient with steel, because aluminum multiplies all the difficulties. A well-done TIG weld is a thing of beauty.

I usually want to weld both sides. I have an inch on the bottom of the inside corners (where the extension force will be) so I plan to put a long tack there. I don't have to run the angles that support the bottom all the way to the corners.

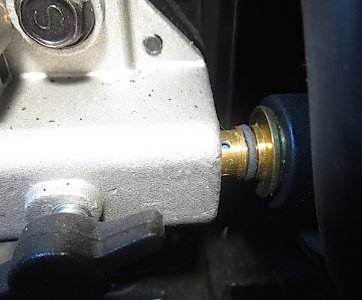

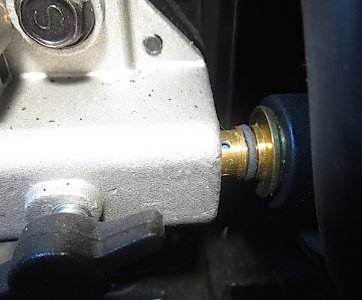

I think I found the problem, thanks to all you guys. You are the best. A picture is worth a thousand words, so here. I suppose I would have eventually found this, but it hadn't occurred to me yet until I posted here. Once you are looking for it, it is pretty glaring.

I usually want to weld both sides. I have an inch on the bottom of the inside corners (where the extension force will be) so I plan to put a long tack there. I don't have to run the angles that support the bottom all the way to the corners.

I think I found the problem, thanks to all you guys. You are the best. A picture is worth a thousand words, so here. I suppose I would have eventually found this, but it hadn't occurred to me yet until I posted here. Once you are looking for it, it is pretty glaring.