Thanks, TD. Stefan's videos are definitely the best intro I've seen.

A little more progress today.

First, a brief video of a part that is hinging perfectly (for Brino and anyone else that's curious). This is what you're after:

I put it in a few more passes on the first side of the shortest part. I quit when I got to this stage:

I'm still not satisfied even though it's about 40 PPI. It's a little hard to see in the photo, but the entire left edge is still low. If you look closely, it's only bearing on a very few points anywhere within about an eighth of an inch of the left edge. Not good since this edge is a critical surface for checking narrow dovetails.

Keep in mind that I still barely know what I'm doing. I've got weeks of practice, not years.

Anyway, another thing I've learned is to use

all your senses. Here's a photo of me licking the part to detect a low spot:

(Kidding)

In all sincerity, though, pretty much all your other senses are involved. You can feel the part sucking onto the plate when it's flat. If it isn't hinging perfectly, your fingers will tell you before your eyes (one side might be easier to swing than the other, for example).

In my case, I could actually

see the low spot along the edge. Hard to set up decent lighting to show it in a photograph, but in person the low spot is directly visible. You can sort of see it in this photo:

(

Edit: I was completely wrong about this. The dark stripes along the edge weren't low, they were a side effect of the casting process. See my follow up post later in the thread.)

See the dark spot along the left edge?

(Edit: again, not a low spot, despite appearances. I'm an idiot)

I actually need to back up a bit, stop pinpointing, and go at almost the entire surface with slightly longer scrapes to lower the rest of the part to this level before continuing. (More on this later.)

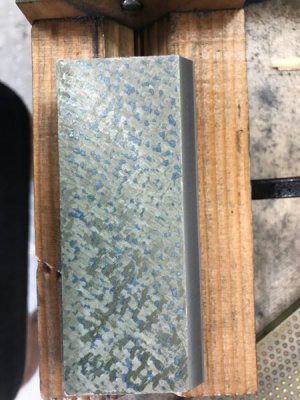

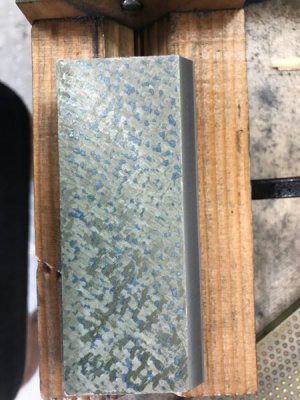

Before getting carried away, I decided to start working on the other surface for a bit. Here's the new surface around five passes after scraping away the mill marks:

(Note the rag to give a little protection to the already scraped surface.)

This side started off pretty flat right after power scraping the mill marks off, so I started hand scraping almost immediately.

This is what it looked like right after scraping off the blue peaks shown above:

Notice the length of the scrapes (about a half inch mostly, since I'm still at a medium roughing stage).

Here is the marking immediately after that pass:

So now I went at it from the other direction:

After several more passes, most of the "valleys" had at least a few bearing points showing, and I got to around 15-20 PPI.

At that point I started "bump" scraping (more later):

Notice the much shorter scrapes. I'm targeting each individual blue spot now, trying to just take off the absolute peak of each individual mark. Notice where I missed a few but just kept going trying to keep the 45 degree rows fairly neat and straight, and trying to scrape to the same depth each time.

Arguably, I could have gone a few more passes still before starting to bump scrape, but none of the valleys were even dime sized so it seemed a reasonable time to start.

After just a few more passes I had it in even better shape than the first side:

You can also tell visually that this side is in better shape than the first:

Before getting too cocky, though I should point out that even canode spotting ink is too thick to REALLY claim success. The ultimate test is to flood the part with alcohol, then let it evaporate to create a slightly dull haze. Then rub the part on a dry surface plate.

This time the lighting and photography is REALLY tricky:

Those dark glints you see are high spots. They are actually evenly spread over the surface of the part, but I'd need to drag out a real camera and lighting equipment to show it better. The blue showed about 40 PPI but these glints are only about 20, sadly.

If I set up decent lighting on my benchtop I could bump scrape even these alcohol marks, but I'd have to do it in the evenings as I have a skylight in my shop. I'm pretty confident I could get it flat down to about 50 millionths of an inch that way (if I wanted to drive myself crazy).

Anyway, I still need to fix the first side.

I was tired of the tedious finish scraping though, so I decided to start on the 8" part next.