- Joined

- Apr 21, 2015

- Messages

- 653

I recently completed Richard King's week long scraping class, and I've made it most of the way through the Connelly book. This, of course, now makes me a certified expert in scraping and machine rebuilding. (Not!)

Just kidding. After several weeks scraping in a cast iron box square casting, I'm increasingly confident in my ability to scrape flat, parallel and square, but I'm still a clueless newbie when it comes to scraping in dovetails and actual machine ways.

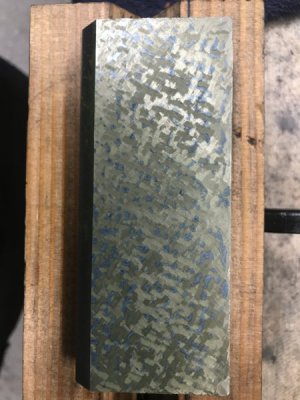

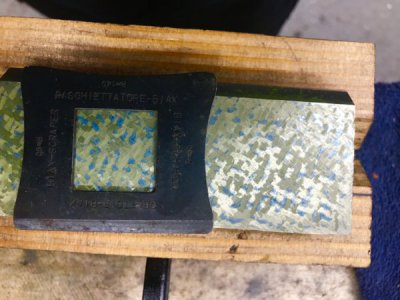

Here's the box square / transfer block I made:

After spending a month working on that sucker, I also took the time to make a nice felt-lined, finger-jointed wooden box to store it. On Richard's recommendation, I built the case to store the square on end (as it is in the photo) rather than horizontal. The thought being that horizontal storage might lead to a slight bow developing over time. I forgot to photograph the box, but I'll post it if anyone is interested.

I now want to start scraping in my little Logan lathe, especially the replacement cross-slide I made for it. The bed ways are hardened, but the cross slide, compound ways, and compound rotary ways are all fair game.

Before I can do that, though, I needed some small straightedges. Yay! More tools to make.

I purchased a small hunk of cast iron, 12" x 2 1/4" x 1 1/4" with the goal of making three small dovetail gages: one 12" long, one 7.5", and one 4.5".

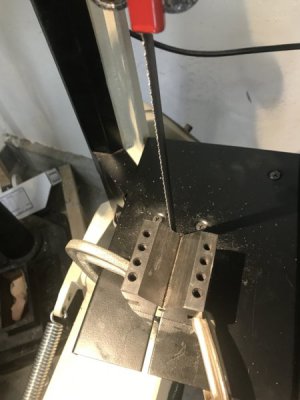

Rather than mill away half the block, I painstakingly set up my horizontal bandsaw for vertical use and clamped a v-block to the table:

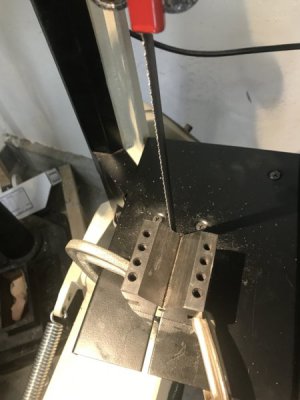

Then I spent what felt like hours slicing the bar in half:

Then I realized I should have milled all the square edges first instead of leaving them rough.

After puzzling for a bit, I eventually figured out how to get the wide edges milled flat (workholding 101). Since I plan to make handles eventually, I drilled and tapped 5/16-18 holes in the ends of each half bar to aid in clamping:

Not the most robust workholding, but it sufficed with light cuts and slow feeds.

Then I milled the smaller edges in the vise. I wasn't worried about any flex from the overhang since I'm going to scrape it in anyway:

Finally, I used a pair of small v-blocks to mill the 45 degree side:

Then I just had to cut one of the 12" wedges into two parts to get the three sizes I wanted with little waste.

I then stress relieved the bars by hanging them from one end and beating on them with a hammer for a bit. I also left the outside for a few days and plan to sacrifice a chicken next weekend. (Seriously, I think these are small enough that they shouldn't move too much, and if they do I can always rescrape them periodically until they relax.)

Yesterday, I made a little wooden fixture to hold the work securely as I start scraping them in. I decide to start with the little guy and work up to the 12" one:

That's all for now. I'll post updates as I complete the scraping.

Regards,

--

Rex

Just kidding. After several weeks scraping in a cast iron box square casting, I'm increasingly confident in my ability to scrape flat, parallel and square, but I'm still a clueless newbie when it comes to scraping in dovetails and actual machine ways.

Here's the box square / transfer block I made:

After spending a month working on that sucker, I also took the time to make a nice felt-lined, finger-jointed wooden box to store it. On Richard's recommendation, I built the case to store the square on end (as it is in the photo) rather than horizontal. The thought being that horizontal storage might lead to a slight bow developing over time. I forgot to photograph the box, but I'll post it if anyone is interested.

I now want to start scraping in my little Logan lathe, especially the replacement cross-slide I made for it. The bed ways are hardened, but the cross slide, compound ways, and compound rotary ways are all fair game.

Before I can do that, though, I needed some small straightedges. Yay! More tools to make.

I purchased a small hunk of cast iron, 12" x 2 1/4" x 1 1/4" with the goal of making three small dovetail gages: one 12" long, one 7.5", and one 4.5".

Rather than mill away half the block, I painstakingly set up my horizontal bandsaw for vertical use and clamped a v-block to the table:

Then I spent what felt like hours slicing the bar in half:

Then I realized I should have milled all the square edges first instead of leaving them rough.

After puzzling for a bit, I eventually figured out how to get the wide edges milled flat (workholding 101). Since I plan to make handles eventually, I drilled and tapped 5/16-18 holes in the ends of each half bar to aid in clamping:

Not the most robust workholding, but it sufficed with light cuts and slow feeds.

Then I milled the smaller edges in the vise. I wasn't worried about any flex from the overhang since I'm going to scrape it in anyway:

Finally, I used a pair of small v-blocks to mill the 45 degree side:

Then I just had to cut one of the 12" wedges into two parts to get the three sizes I wanted with little waste.

I then stress relieved the bars by hanging them from one end and beating on them with a hammer for a bit. I also left the outside for a few days and plan to sacrifice a chicken next weekend. (Seriously, I think these are small enough that they shouldn't move too much, and if they do I can always rescrape them periodically until they relax.)

Yesterday, I made a little wooden fixture to hold the work securely as I start scraping them in. I decide to start with the little guy and work up to the 12" one:

That's all for now. I'll post updates as I complete the scraping.

Regards,

--

Rex