-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machining A Replacement Cross Slide For A Logan 11" (as Promised)

- Thread starter Rex Walters

- Start date

- Joined

- Apr 21, 2015

- Messages

- 653

Wowsers! Great job! And whatever mistakes you made on the way were of the non-fatal, low-cost learning variety.

Ha, thanks! Nietzsche learning.

Thanks. Just realized I still need to scribe marks for the compound. Like Paula, I will also scribe four lines at the four points of the compass. Then it's really and truly done.

--

Rex

- Joined

- Jul 31, 2013

- Messages

- 314

Hi

Very nice work, i will have to look into getting the castings for my lathe, a denford viceroy 10 x 22", the cross slide on my lathe as ears or wings.

Very nice work, i will have to look into getting the castings for my lathe, a denford viceroy 10 x 22", the cross slide on my lathe as ears or wings.

- Joined

- Apr 21, 2015

- Messages

- 653

In the first photograph in your previous post (showing a top view of the saddle with the cross-feed nut all the way toward the dial), are there still cross feed screw threads in the nut or did it just run off the threads?

If I understand your question correctly, the cross-feed acme screw is threaded almost the entire way back to the dial end. The threads continue under the covered portion of the saddle, so the nut still has all threads engaged. I'm not sure that question makes sense, though, because if it ran out of threads I wouldn't be able to retract the slide any further (since the remaining part of the rod is as large as the major diameter of the thread).

Did I misunderstand the question?

- Joined

- Dec 25, 2011

- Messages

- 10,552

No. I just didn't know that the Logan was originally built that way. On the Atlas machines, if you start cranking on the cross feed in either direction, the nut will eventually run off of the threads. So unlike with carriage traverse, if you engage power cross feed in either direction, the only way that you can hurt anything is to run the tool post into the work. The Logan carriage covers the cross feed screw much further toward the centerline than does the Atlas. Or maybe it sticks out much further toward the operator. On the Atlas, where the threads stop going toward the operator, the diameter of the screw reduces to the thread minor diameter or a little less. I was wrong in assuming that the Logan did, too. Learned something new.

- Joined

- Apr 21, 2015

- Messages

- 653

Ah. That makes sense.

On my Logan (actually a Montgomery Wards 11" Powr-Kraft circa 1941) you can crank off the back side, but it's not possible to crank off the screw on the near side. If you look at the first photo in comment 18, the threads on the cross-feed screw continue well under the covered portion of the saddle. Since the lathe does have power cross-feed without a clutch, it does seem like a better design if it were possible to run off the screw on the near side as well. I could machine a new screw, but the saddle would also have to leave more room uncovered.

All in all, I love this lathe. To be fair, it's the only one I've ever owned. The only other lathe I've ever actually used is the Jet 14" at the local TechShop in San Jose.

My only small gripes with the lathe were:

My current thinking is actually to make a plastic collar that goes completely around the base (I really like the look and high-contrast of the Harding micrometer dials). If I had a manual engraving machine, I could just laminate some thin white plastic over a black plastic base and then just engrave the letters and tics. I could do the tics easily enough with my vertical mill, but the numbers will require some kind of pantograph engraving setup (unless someone has a better idea). I'm now on the lookout for a small, cheap, used engraving machine (or plans for the same). I'm also thinking about designing a small sliding vise with a pantograph for the vertical mill to use for engraving one letter/figure at a time (ambitious dreams).

Regards,

--

Rex

On my Logan (actually a Montgomery Wards 11" Powr-Kraft circa 1941) you can crank off the back side, but it's not possible to crank off the screw on the near side. If you look at the first photo in comment 18, the threads on the cross-feed screw continue well under the covered portion of the saddle. Since the lathe does have power cross-feed without a clutch, it does seem like a better design if it were possible to run off the screw on the near side as well. I could machine a new screw, but the saddle would also have to leave more room uncovered.

All in all, I love this lathe. To be fair, it's the only one I've ever owned. The only other lathe I've ever actually used is the Jet 14" at the local TechShop in San Jose.

My only small gripes with the lathe were:

- Dials read radially rather than diametric, and the dials were so small that they were hard to read. [Fixed with new hand-made dials!]

- The zero locks for the cross-feed and compound dials are just radial grub screws, which interfere with the view of the dials. I much prefer the axial twist-lock mechanisms on big-boy lathes. [A future project?]

- The cross-feed screw cover that screws onto the back of the cross-slide appears to be zinc or some other non-ferrous material — it won't hold an indicator base. [Fixed with the new cross-slide!]

- Reading the compound angle is a real pain. The witness mark on the cross-slide and the compass gauge marks on the base of the compound slide are both on the far side of the lathe where it's hard to see (even if they weren't old and covered in grime). [Partially fixed with the new cross-slide.]

- The quick-change gear-box interferes with the carriage feed handwheel when it's at the extreme left end of the lathe. Not a problem when using a chuck, but with collets it's a real inconvenience (I have to extend the compound slide much farther than I'd normally like for maximum rigidity. [No solution yet.]

My current thinking is actually to make a plastic collar that goes completely around the base (I really like the look and high-contrast of the Harding micrometer dials). If I had a manual engraving machine, I could just laminate some thin white plastic over a black plastic base and then just engrave the letters and tics. I could do the tics easily enough with my vertical mill, but the numbers will require some kind of pantograph engraving setup (unless someone has a better idea). I'm now on the lookout for a small, cheap, used engraving machine (or plans for the same). I'm also thinking about designing a small sliding vise with a pantograph for the vertical mill to use for engraving one letter/figure at a time (ambitious dreams).

Regards,

--

Rex

- Joined

- Jul 27, 2013

- Messages

- 295

Well;

Pretty brave stuff to undertake, and quite a nice result. Kudos! Dang... I've got to get my lathe done!!!!

Pretty brave stuff to undertake, and quite a nice result. Kudos! Dang... I've got to get my lathe done!!!!

I saw a guy, here I think, make a protractor-like device for setting the compound, using the flat on the cross slide body as the reference surface. Kind of a stepped contraption, iirc. Been thinking about that since, like yours, I have to get a flashlight and magnifying glass to read the angle marks on the compound, and also read from the back side of the machine which means I can't put it against a wall. All your slots offer even more ways to do it like that.

I like your collar idea too, but would still have to figure a way to see it easily from the front. I'll be watching your progress on this. Thanks for the clear pics and write-ups.

I like your collar idea too, but would still have to figure a way to see it easily from the front. I'll be watching your progress on this. Thanks for the clear pics and write-ups.

- Joined

- Apr 21, 2015

- Messages

- 653

Just a quick update after actually using the new cross slide for a simple bit of turning. [I'm making an extended Y-axis crank bushing for my mill to get a little more travel — but that's a topic for another thread.]

It turns out I was over-optimistic on the amount of adjustability available with my quick-change toolpost holders (AXA sized offshore knock-off of an Aloris QCTP).

As I mentioned, the new slide is quite a bit thicker (taller) than the old slide. I didn't think it would be that big a problem, but I was wrong. Many of my tools bottom out when adjusting before getting to center hight. I actually had to grind away the top half of a parting tool yesterday, just to get it down to center height.

So I'm going to have to skim a bit more off the top of the new slide before engraving the witness marks for the compound. Because the tee-slots are already milled, though, I can't take too much material off the top of the slide before the bearing parts of the slots become too thin to use. I don't want to thin them much less than 1/8". I'm probably over-cautious since there is normally something on top for the clamping bolts to bear against, but I expect there will occasionally be times when I'm clamping something hollow on the tee-slots.

Since I've also already milled the dovetails on the bottom, I can't take material off from the bottom (the dovetail slots would become too wide).

I suspect I'll have to take some material off of the compound as well. This isn't the end of the world, though, as my compound has seen a lot of use — taking some material off the top of the compound would actually help to clean it up.

So remaining work on the slide includes:

- Adjusting the thickness/height.

- Adding witness marks for the compound protractor gauge (and re-marking the protractor on the compound somehow so it has marks the full 360 degrees around the compound instead of just in the rear).

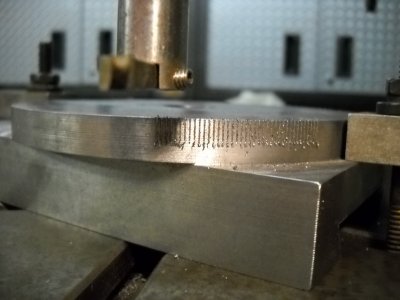

- Scraping the dovetail ways flat on both the slide and the saddle. [I've been practicing scraping on my "transfer block" casting. I think I'm getting the hang of it.]

- Painting. [I'll definitely wait until I strip and re-paint the compound and saddle as well. Maybe someday. I hate painting.]

- Making a rear-mount toolpost holder. [That will be another thread.]

It turns out I was over-optimistic on the amount of adjustability available with my quick-change toolpost holders (AXA sized offshore knock-off of an Aloris QCTP).

As I mentioned, the new slide is quite a bit thicker (taller) than the old slide. I didn't think it would be that big a problem, but I was wrong. Many of my tools bottom out when adjusting before getting to center hight. I actually had to grind away the top half of a parting tool yesterday, just to get it down to center height.

So I'm going to have to skim a bit more off the top of the new slide before engraving the witness marks for the compound. Because the tee-slots are already milled, though, I can't take too much material off the top of the slide before the bearing parts of the slots become too thin to use. I don't want to thin them much less than 1/8". I'm probably over-cautious since there is normally something on top for the clamping bolts to bear against, but I expect there will occasionally be times when I'm clamping something hollow on the tee-slots.

Since I've also already milled the dovetails on the bottom, I can't take material off from the bottom (the dovetail slots would become too wide).

I suspect I'll have to take some material off of the compound as well. This isn't the end of the world, though, as my compound has seen a lot of use — taking some material off the top of the compound would actually help to clean it up.

So remaining work on the slide includes:

- Adjusting the thickness/height.

- Adding witness marks for the compound protractor gauge (and re-marking the protractor on the compound somehow so it has marks the full 360 degrees around the compound instead of just in the rear).

- Scraping the dovetail ways flat on both the slide and the saddle. [I've been practicing scraping on my "transfer block" casting. I think I'm getting the hang of it.]

- Painting. [I'll definitely wait until I strip and re-paint the compound and saddle as well. Maybe someday. I hate painting.]

- Making a rear-mount toolpost holder. [That will be another thread.]

4

4GSR

Forum Guest

Register Today