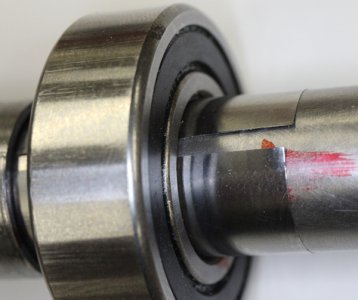

I tried the same Loctite retainer on the carbon steel shim on my 1018 scrap shaft. Same result, peeled off just as easily as the brass. You can see the green stripe within the red felt pen lines where its entirely cured but just no gription.

Then I tried medium viscosity CA glue (between the blue lines). It stuck better, but not anything like what I would call a permanent bond. It would probably stay put if you were sliding a loose fit bearing over it but I'm not sure how much shear stress it would take before failing

Very strange. I don't know what to say about this anymore. I know CA prefers a bit of porosity. But makes me wonder how bearings can stay so firmly stuck to a shaft with normal Loctite retainer where you sometimes have to beat them or torch heat to remove. Maybe its purely better strength in shear (like pushing a bearing off along a shaft or machining a part bonded to an arbor face) vs tensile strength (peeling back a thin stock). Interestingly the 'glue' is always fully cured to the shaft but not to the shim stock, I need to talk to a Loctite engineer, this will follow me to my grave LOL!

Then I tried medium viscosity CA glue (between the blue lines). It stuck better, but not anything like what I would call a permanent bond. It would probably stay put if you were sliding a loose fit bearing over it but I'm not sure how much shear stress it would take before failing

Very strange. I don't know what to say about this anymore. I know CA prefers a bit of porosity. But makes me wonder how bearings can stay so firmly stuck to a shaft with normal Loctite retainer where you sometimes have to beat them or torch heat to remove. Maybe its purely better strength in shear (like pushing a bearing off along a shaft or machining a part bonded to an arbor face) vs tensile strength (peeling back a thin stock). Interestingly the 'glue' is always fully cured to the shaft but not to the shim stock, I need to talk to a Loctite engineer, this will follow me to my grave LOL!

Attachments

Last edited: