- Joined

- Mar 12, 2021

- Messages

- 68

Hello,

Sorry if this should be under the grizzly sub forum but figured as its purely electrical issue here would be the best place. In short during transport to me lathe had its motor disconnected from the control box and don't have a before picture but have nice labels on the wires and several schematics but I'm not quite as familiar with AC motors to put the necessary pieces together to figure out for sure what wire goes to what.

it was/still will be setup for household 220/240

On the motor I have wires numbered 1 thru 6. Numbers 1 thru 4 are black 5 and 6 are red

From the control box I have ground, U1 (brown) V5 (blue) W4 (black)

this I believe is the overview of the control box (I am unsure if reverse worked its been a few months but i think it did, and pretty sure that button is wired in)

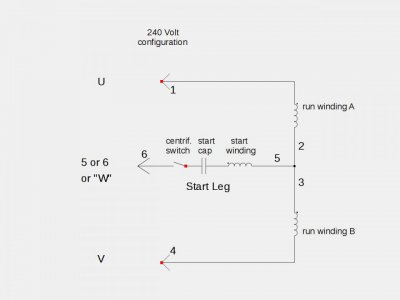

Here is what the grizzly manual shows for the motor setup for 220V

this is the wiring diagram from the Rong FU manual (OEM) and this at least has matching labels saying that U1 V5 and W4 go to the motor.

lastly this is the diagram from the motor wiring housing cover.

I have no issues probing things with a multi meter but have a respectful fear with messing with electricity that i don't fully understand, as i don't want to let out any magical blue smoke or make popcorn.

I did find one thread on wiring for the Busybee variant of this machine but in the end the info was just wire colors that match mine. i feel like i have all the information I just personally don't have the skills to piece it together at least not yet.

Thanks!

Sorry if this should be under the grizzly sub forum but figured as its purely electrical issue here would be the best place. In short during transport to me lathe had its motor disconnected from the control box and don't have a before picture but have nice labels on the wires and several schematics but I'm not quite as familiar with AC motors to put the necessary pieces together to figure out for sure what wire goes to what.

it was/still will be setup for household 220/240

On the motor I have wires numbered 1 thru 6. Numbers 1 thru 4 are black 5 and 6 are red

From the control box I have ground, U1 (brown) V5 (blue) W4 (black)

this I believe is the overview of the control box (I am unsure if reverse worked its been a few months but i think it did, and pretty sure that button is wired in)

Here is what the grizzly manual shows for the motor setup for 220V

this is the wiring diagram from the Rong FU manual (OEM) and this at least has matching labels saying that U1 V5 and W4 go to the motor.

lastly this is the diagram from the motor wiring housing cover.

I have no issues probing things with a multi meter but have a respectful fear with messing with electricity that i don't fully understand, as i don't want to let out any magical blue smoke or make popcorn.

I did find one thread on wiring for the Busybee variant of this machine but in the end the info was just wire colors that match mine. i feel like i have all the information I just personally don't have the skills to piece it together at least not yet.

Thanks!