-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling machine motor wiring

- Thread starter Pevehouse

- Start date

- Joined

- Apr 30, 2015

- Messages

- 12,566

And so far it only runs in forward? Even when you select milling / drilling and push the reverse button?

If it runs in one direction now the motor wiring should be fine- the problem is in the reversing hardware in the box

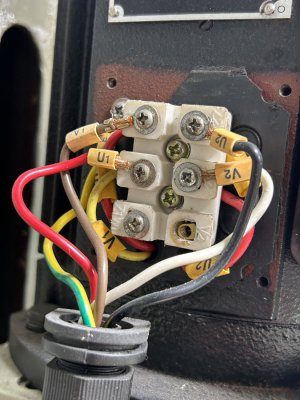

To prove it, swap the U1 and U2 motor wires (with power off of course)

Then the motor should only run in reverse, which proves the motor is ok and will run in either direction

The straps are only for dual voltage motors which you don't have

If it runs in one direction now the motor wiring should be fine- the problem is in the reversing hardware in the box

To prove it, swap the U1 and U2 motor wires (with power off of course)

Then the motor should only run in reverse, which proves the motor is ok and will run in either direction

The straps are only for dual voltage motors which you don't have

Last edited:

- Joined

- Apr 30, 2015

- Messages

- 12,566

I watched a youtube video of it in tapping mode and it's clear to me that it needs to have a 3-phase motor for instant reverse tapping. And the machine does not automatically reverse- you have to push the reverse button, according to the video

The machine may operate differently with a single phase motor. It might be that the microswitches can be adjusted to stop the motor when the quill reaches a certain depth, then the reverse mode can be selected. I'm not sure, but the motor would have to stop first before reversing.

The machine may operate differently with a single phase motor. It might be that the microswitches can be adjusted to stop the motor when the quill reaches a certain depth, then the reverse mode can be selected. I'm not sure, but the motor would have to stop first before reversing.

Last edited:

Ok, that makes sense. I have not had a chance to swap the wires around. I have the quill out of it at the moment and the oil drained out, so I don’t want to run it dry. I hope to have all that back together this weekend. That may be a 3 phas machine they show there. Never can tell with the Chinese,lol. I would like to get it operating as close to design as possible is all. Doesn’t have to be perfectI watched a youtube video of it in tapping mode and it's clear to me that it needs to have a 3-phase motor for instant reverse tapping. And the machine does not automatically reverse- you have to push the reverse button, according to the video

The machine may operate differently with a single phase motor. It might be that the microswitches can be adjusted to stop the motor when the quill reaches a certain depth, then the reverse mode can be selected. I'm not sure, but the motor would have to stop first before reversing.

- Joined

- Feb 2, 2013

- Messages

- 4,129

I have access to a set of copper bus bars for your motor, you are welcome to them.

You can also make a set of jumper wires too

You can also make a set of jumper wires too

I made a couple of jumper wires. I can try those and if for some reason I run into a problem I may take you up on thatI have access to a set of copper bus bars for your motor, you are welcome to them.

You can also make a set of jumper wires too

- Joined

- Apr 30, 2015

- Messages

- 12,566

AFAIK You shouldn't need any jumpers- the factory motor wiring looks ok

I noticed the schematic diagram in your manual doesn't match the machine at all;

The diagram shows only two contactors but your machine has six- the manual diagram looks like it's for a lathe

That's a bummer- I don't know how far we can get

You should call Bolton's engineering department and howl (if they even still have an engineering department- they used to)

Let me know when you get the head back together

I noticed the schematic diagram in your manual doesn't match the machine at all;

The diagram shows only two contactors but your machine has six- the manual diagram looks like it's for a lathe

That's a bummer- I don't know how far we can get

You should call Bolton's engineering department and howl (if they even still have an engineering department- they used to)

Let me know when you get the head back together

Last edited: