- Joined

- Mar 30, 2024

- Messages

- 23

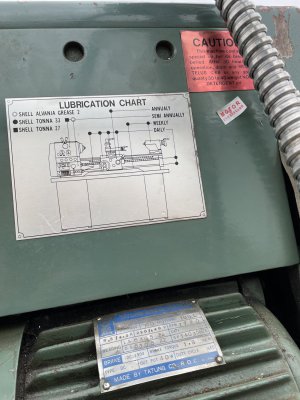

Here’s my JET 12040PD that I picked up about a month ago. There’s not many examples of this particular machine that I’ve found on the internet specifically. I know there’s similar machines as this was produced by Dashin Prince. I’m an off-road fabricator not a machinist so bear with my newb-ness.

I’ll share my progress and ask my questions here. I like pictures. Hope y’all do too.

It’s a fun story of how I traveled to purchase this sight unseen while I had a fortunate break in winter weather across Nd and Mn and how I tried to enter Canada to visit family with it before returning home. Canada was not happy with me and refused entry. Whatever, they’re just mad they don’t use Pennie’s anymore. What you see above is what it came with.

Some more details about it:

1982 manufacture date 3767 serial number

3HP factory upgrade option

Gap bed

Coolant pump

Imperial & metric dial readouts

Awesome pool ball handles

Foot brake (maybe that’s obvious but it was unknown to me before I laid eyes on it so I was excited)

I’ll share my progress and ask my questions here. I like pictures. Hope y’all do too.

It’s a fun story of how I traveled to purchase this sight unseen while I had a fortunate break in winter weather across Nd and Mn and how I tried to enter Canada to visit family with it before returning home. Canada was not happy with me and refused entry. Whatever, they’re just mad they don’t use Pennie’s anymore. What you see above is what it came with.

Some more details about it:

1982 manufacture date 3767 serial number

3HP factory upgrade option

Gap bed

Coolant pump

Imperial & metric dial readouts

Awesome pool ball handles

Foot brake (maybe that’s obvious but it was unknown to me before I laid eyes on it so I was excited)