- Joined

- Feb 25, 2021

- Messages

- 3,271

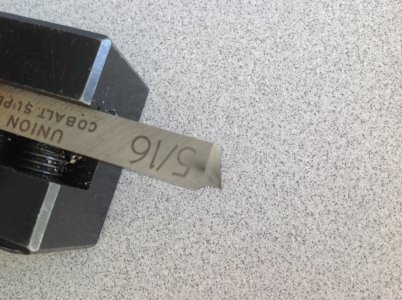

Finest I have right now is the 1500. Do you have any experience comparing the 1500 to 2000 for HSS? (Should I rush out and buy a 2000?) I would think it may be more important for carbide.I bought the 8" diamond lapping plates in 80, 120, 360, 400, 600, 800, 1200, 1500 and 2000 grit.

I have the ability to move material or bring to a mirror finish.

Have you compared Shars M42 to U.S. made M42? I'm wondering how much is M42 (which I would guess is significant) and how much is U.S vs import (discount) quality?