Absolutely, in getting it working I had one servo runaway with the belts attached, magmotors at full spin are terrifying fast, I was luckily able to estop before the axis hit its endstop but in my mind that could have cracked the cast iron and I"d have a 3000lb paperweight in my basement.

I'm putting /huge/ rubber bumpers at the ends of travel due to being paranoid, but this thing is /awesome/ compared to the hobby mill, even at the above "conservative" 15ipm / .1 doc / less than half cutter engagement I can make the run for that part in the first post in under 5 minutes, that was like a 20 minute job before, plus fixtures/indicating because I could never get a big enough vice in the little one, and I'm not even going /fast/ yet.

It is pretty exciting that I am this close to getting it running, I'm close to a year in on this project, hah.

I'm putting /huge/ rubber bumpers at the ends of travel due to being paranoid, but this thing is /awesome/ compared to the hobby mill, even at the above "conservative" 15ipm / .1 doc / less than half cutter engagement I can make the run for that part in the first post in under 5 minutes, that was like a 20 minute job before, plus fixtures/indicating because I could never get a big enough vice in the little one, and I'm not even going /fast/ yet.

It is pretty exciting that I am this close to getting it running, I'm close to a year in on this project, hah.

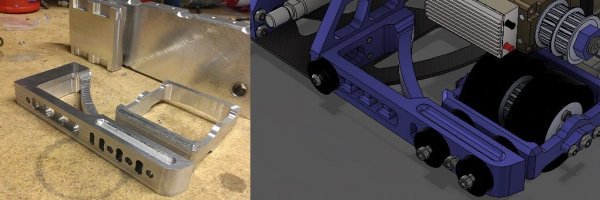

That is a complex part, looking good!

That is a complex part, looking good! I remember seeing that screen.

I remember seeing that screen.