Does it specifically need to be that Vertex chuck for some reason? There are other options & for less money. If you get a front mount chuck you could bolt the chuck directly to your rotary table with just long bolts & t-nuts, no backplate needed, assuming your rotary table has 4 slots instead of 3.

Search for K72-200. It will be sold under various familiar & generic brand names which will vary in price.

Do you need it to be 4-jaw independent? I didn't so I just went with a scroll chuck & a backplate which I can just dial in when mounting the backplate to the RT. I also have an 8" Vertex RT but I decided to go with a 6.25" chuck & a backplate for a few reasons. Weight being an important factor.

The smaller chuck & backplate allows me to bolt the chuck directly to my mill table which has came in handy quite a few times for me.

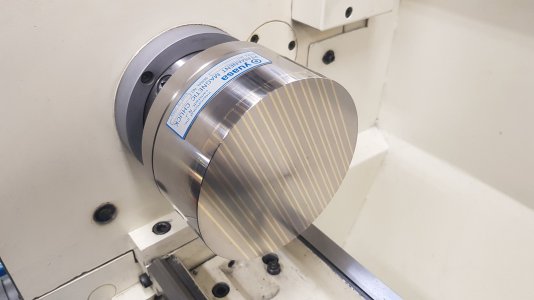

View attachment 511865

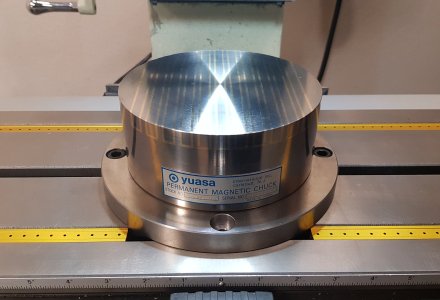

View attachment 511866